CNC machining has become the backbone of modern manufacturing, enabling manufacturers to produce complex, high-precision parts with speed, consistency, and scalability. From aerospace and automotive components to medical devices and industrial tooling, CNC technology delivers unmatched accuracy and repeatability.

In this article, we’ll explore what CNC machining is, how it works, the different types of CNC Machining Centers, and why advanced systems—such as 5 axis CNC Machining Centers and vertical Machining Centers—are redefining metal processing efficiency.

Understanding CNC Machining

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process where computer software controls machine tools to remove material from a workpiece and shape it into a precise final form.

Unlike manual machining, CNC systems rely on digital programs (G-code) to dictate cutting paths, speeds, and tool movements. This automation dramatically reduces human error while increasing productivity and dimensional accuracy.

A modern CNC machining center integrates milling, drilling, tapping, and sometimes turning operations into a single automated platform, making it ideal for high-volume and high-precision manufacturing.

How CNC Machining Works: Step-by-Step

1. Digital Design (CAD)

The process begins with a CAD (Computer-Aided Design) model that defines the part’s geometry, tolerances, and features.

2. Toolpath Programming (CAM)

CAM software converts the CAD file into machine-readable instructions, specifying tool selection, spindle speed, feed rate, and cutting sequence.

3. Machine Setup

The workpiece is securely clamped on the worktable, tools are loaded into the tool magazine, and reference points are calibrated.

4. Automated Machining

Once initiated, the vertical CNC machine or CNC turning center executes the programmed operations with extreme precision, producing consistent parts from batch to batch.

5. Inspection and Finishing

Finished components are inspected for dimensional accuracy and surface quality. Additional finishing processes may be applied if required.

Types of CNC Machining Centers

CNC Machining Center

A machining center is a multifunctional CNC machine capable of performing multiple machining operations in one setup. These machines are essential for complex parts that require tight tolerances.

Vertical Machining Center (VMC)

A vertical machining center features a vertically oriented spindle, making it ideal for flat surfaces, slots, pockets, and drilling operations.

Advantages of a vertical CNC machine include:

Compact footprint

Easy setup and operation

Excellent visibility of the machining process

High cost-performance ratio

Multi-Axis CNC Machining Explained

4 Axis CNC Machining Center

A 4 axis CNC machining center adds rotational movement to the standard X/Y/Z axes, allowing machining on multiple sides of a workpiece without repositioning.

5 Axis Machining

5 axis machining represents the pinnacle of CNC technology. By enabling simultaneous movement along five axes, it allows:

Complex geometry machining

Reduced setup time

Higher surface finish quality

Improved accuracy on intricate components

A 5 axis mill or 5 axis CNC machining center is widely used in aerospace, automotive, and high-end mold manufacturing.

CNC Turning Center vs. Milling Machines

While milling machines remove material using rotating cutting tools, a CNC turning center rotates the workpiece itself while stationary tools shape it.

Turning centers are ideal for:

Shafts

Bushings

Cylindrical and conical parts

Many advanced machining facilities combine vertical machining centers and CNC turning centers to create flexible, end-to-end production lines.

Key Features of a New Generation CNC Machining Center

Modern CNC equipment is designed not just for accuracy, but also for usability, efficiency, and long-term stability.

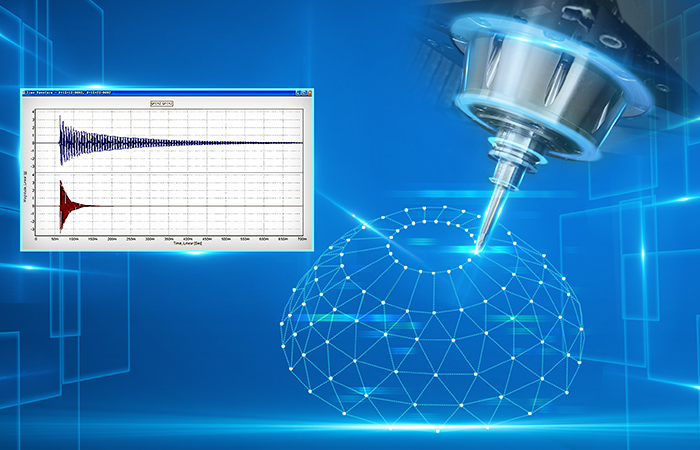

New Generation of CNC Control System

Advanced control systems offer faster data processing, smoother motion control, and improved reliability, enabling complex machining with minimal downtime.

High-Efficiency and High-Accuracy Machining

Optimized spindle performance and rigid structures allow for faster cutting speeds without sacrificing precision.

Excellent Human-Machine Interaction Interface

An intuitive interface ensures simple operation, reducing training time and improving workflow efficiency.

Excellent Metal Machining Performance

From aluminum and steel to titanium alloys, CNC machines deliver stable, consistent performance across a wide range of materials.

Good Anti-Vibration Performance

A rigid machine structure minimizes vibration, enhancing surface finish quality and extending tool life.

Automatic Cleaning Function

Built-in automatic cleaning systems make machine maintenance easier, reducing downtime and improving shop cleanliness.

Typical CNC Machining Center Specifications

A standard high-performance CNC machining center may include the following technical parameters:

X/Y/Z Travel: 500 / 400 / 200 mm

Work Table Dimension: 500 × 400 mm

Max Workpiece Height: 280 mm

Max Load of Worktable: 200 kg

Machine Net Dimension: 2200 × 2000 × 2400 mm

Machine Net Weight: 4000 kg

These specifications ensure stable machining for medium-sized precision components while maintaining excellent rigidity and accuracy.

Applications of CNC Machining

CNC machining plays a critical role across numerous industries:

Aerospace

5 axis machining is essential for producing complex, lightweight components with strict tolerances.

Automotive

From engine blocks to transmission parts, CNC machining ensures durability and consistency.

Medical Devices

Precision CNC machining is vital for implants, surgical instruments, and diagnostic equipment.

Mold & Tooling

CNC machining centers are widely used for mold cavities, cores, and precision tooling components.

Industrial Equipment

High-strength metal parts for machinery and automation systems are commonly CNC machined.

Advantages of CNC Machining

High precision and repeatability

Reduced labor costs

Shorter production cycles

Excellent surface finish

Capability to machine complex geometries

Scalable for mass production

With the integration of 5 axis CNC machining centers and intelligent control systems, manufacturers can achieve unprecedented levels of productivity.

CNC Machining vs. Traditional Machining

Aspect | CNC Machining | Traditional Machining |

Precision | Extremely high | Operator-dependent |

Efficiency | Automated, fast | Slower |

Complexity | Handles complex parts | Limited |

Repeatability | Excellent | Inconsistent |

Labor | Reduced | High |

The Future of CNC Machining

The future of CNC machining lies in:

Smart factories

AI-assisted programming

Digital twins

Real-time monitoring

Advanced 5 axis machining technologies

As CNC systems continue to evolve, manufacturers will benefit from even higher efficiency, flexibility, and sustainability.

Conclusion

So, what is CNC machining and how does it work?

It is a computer-controlled manufacturing process that transforms digital designs into high-precision physical parts using advanced machinery such as vertical machining centers, CNC turning centers, and 5 axis CNC machining centers.

With features like high-efficiency and high-accuracy machining, excellent human-machine interaction, and robust anti-vibration performance, modern CNC machining centers are indispensable in today’s competitive manufacturing landscape.

Whether you are producing simple components or highly complex geometries, CNC machining delivers the precision, reliability, and scalability required for modern industrial success.