Today’s NC machine tools also integrate high-speed servo motors and low-inertia ball screws, improving overall machining responsiveness.

Key benefits include:The evolution of machining continues to accelerate as manufacturers worldwide demand greater precision, higher speeds, and more stable long-term performance. In this rapidly advancing landscape, NC machine tool technology has progressed from simple numerical control to highly intelligent, high-speed, and high-accuracy systems. Among these innovations, the development of CNC High Speed Machine platforms has become a benchmark for modern manufacturing, enabling industries such as aerospace, automotive, medical devices, electronics, and precision molds to achieve unprecedented efficiency.

One excellent example of next-generation innovation is the JTGK-600G CNC High Speed Machine—a model designed around high rigidity, stable accuracy, temperature-controlled machining, and advanced CNC technology. In this article, we’ll explore the latest innovations pushing the NC machining world forward and how machines like this one represent the future of intelligent manufacturing.

1. Smarter CNC Systems Drive High-Speed, High-Accuracy Machining

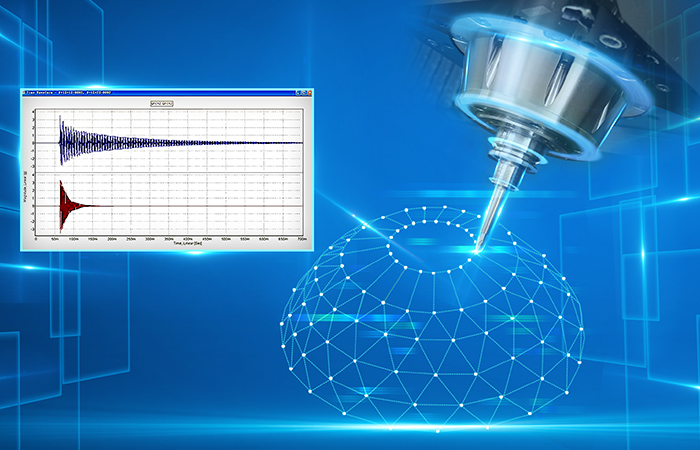

One of the most groundbreaking innovations in NC machining is the adoption of new-generation CNC control systems. Modern high-speed CNC platforms offer faster response times, smoother tool paths, and more efficient servo control. These features are essential as industries require tighter tolerances and faster production cycles.

The JTGK-600G CNC High Speed Machine exemplifies this advancement with its upgraded CNC control system, eliminating lag, reducing vibration, and delivering stable machining at high speeds. This makes it comparable to world-class systems found in brands such as Makino CNC mill machines—known for their accuracy and efficiency in high-speed cutting.

Benefits of new CNC systems include:

Ultra-smooth tool path transitions

Higher interpolation accuracy

Reduced machining defects

Improved synchronization between axes

Faster response to dynamic machining requirements

For workshops requiring reliable high-speed cutting, machines with advanced CNC control like this one outperform older tools CNC milling machine technologies by maintaining maximum stability even under heavy loads.

2. Temperature Control Technology—A Breakthrough for Long-Term Precision

Thermal stability is one of the biggest challenges in high-speed machining. When a machine runs at high RPMs, heat naturally builds up in the spindle, motors, and structural components. Over time, this heat affects accuracy and causes drift.

To solve this, next-generation NC machine tools now incorporate precision temperature control technology.

The JTGK-600G high speed CNC machine includes advanced thermal compensation and cooling features, ensuring the machine maintains stable geometric accuracy even during long machining cycles. This innovation significantly extends machine lifespan and reduces tolerance errors caused by heat expansion.

Advantages of temperature control technology include:

Guarantees continuous cutting accuracy

Stabilizes spindle temperature and prolongs its life

Reduces deformation of machine structure

Prevents machining errors in long-cycle jobs

This is a key feature for precision machining applications such as automotive molds, semiconductor components, medical device housings, and aerospace precision fittings.

3. Structural Optimization for Higher Rigidity and Stability

High-speed machining requires exceptional machine rigidity because rapid tool movements and high-frequency vibrations generate substantial mechanical stress. The newest NC machine tool platforms incorporate reinforced structural frameworks, thicker castings, and optimized weight distribution.

The JTGK-600G CNC High Speed Machine adopts a new structure design that significantly enhances rigidity. The reinforced frame, optimized weight balance, and stable column design allow the machine to withstand heavy cutting forces without vibration. This results in smoother surface finishes, longer tool life, and reduced machining errors.

Compared with older-generation tools CNC milling machines, this design brings:

Higher rigidity during heavy cutting

Better vibration absorption

Improved long-term durability

Enhanced reliability under repeated high-speed cycles

Structural optimization is one of the most impactful innovations in modern NC machining, and it’s a cornerstone of machines like the JTGK-600G.

4. High-Speed Spindle and Feed System Advancements

Modern CNC high speed machine solutions rely heavily on spindle technology. Advancements in spindle bearings, lubrication, and dynamic balance enable faster rotation without compromising accuracy.

Faster cutting speeds

Reduced cycle times

Higher productivity for mass production

Excellent surface finishing at high RPM

Stable performance in micro-cutting and mold engraving

These characteristics are vital for industries requiring detailed and precise machining, such as consumer electronics casings, 3C products, and medical device micro-components.

5. The Rise of Compact, Space-Saving Machine Designs

As workshops demand more Automation and higher output in limited spaces, machine builders have developed compact NC machine tool designs without sacrificing performance.

The JTGK-600G high speed CNC center stands out with its efficient and compact footprint:

2030 × 2200 × 2450mm (Circular Type Tool Magazine)

2260 × 2200 × 2450mm (Chain Type Tool Magazine)

Its all-in-one compact design makes floor planning easier while maintaining machine rigidity. For factories with limited layout space, this is a major advantage over older or larger Makino CNC mill-style machines.

6. Enhanced Automation and Hybrid NC-CNC Capabilities

Modern NC machine tool technology integrates more automation features:

Auto tool changers

Tool breakage detection

Smart lubrication

Optional fully closed-loop systems

Automated temperature compensation

Remote diagnostic monitoring

The JTGK-600G supports a rotary magazine or chain-type magazine for automated tool changes, enhancing productivity and reducing manual intervention. This places the machine among the top choices for workshops upgrading to modern automation standards.

7. Detailed Product Overview: JTGK-600G CNC High Speed Machine

Below are the key specifications that define the machine’s professional capabilities:

Travel

X/Y/Z Travel: 600 / 500 / 300 mm

Worktable

Dimension: 650 × 500 mm

Max Workpiece Size: 650 × 500 × 330 mm

Max Load: 300 kg

Machine Dimensions

Circular Tool Magazine: 2030 × 2200 × 2450 mm

Chain Tool Magazine: 2260 × 2200 × 2450 mm

Weight

Machine Net Weight: 6000 kg

Innovation Features

New generation CNC system

Temperature control for long-term accuracy

High-rigidity structure

Stable and reliable machining performance

This combination of features places the JTGK-600G among top-performing high speed CNC centers in its category.

8. Why These Innovations Matter for Modern Manufacturing

The world of machining is becoming increasingly competitive. Faster speeds, higher accuracy, and consistent quality are no longer optional—they're mandatory. Innovations in NC machine tool technology directly translate into:

Higher production efficiency

Reduced scrap rates

Lower tool wear

More stable cutting performance

Better surface finish quality

Lower operating costs

Machines like the JTGK-600G make it possible for manufacturers to stay competitive while maintaining superior quality.

Conclusion

The latest innovations in NC machine tool technology—advanced CNC systems, thermal stability, structural improvements, compact machine design, and automation—have transformed modern machining. The JTGK-600G CNC High Speed Machine is a strong representation of these advancements, offering a powerful combination of speed, accuracy, and long-term reliability.

With industries demanding more precise, faster, and more stable machining capabilities, high-speed machines like the JTGK-600G are becoming essential tools for workshops seeking improved productivity and global competitiveness.