Choosing the right CNC Machining Center is crucial for achieving precision, efficiency, and flexibility in modern manufacturing. As global industries demand increasingly complex components and higher production volumes, understanding the functional differences between vertical and horizontal CNC Machining Centers becomes essential for making the best investment decision. Each configuration has unique strengths, but one standout solution in the vertical CNC category is the JTGK-500F Pro CNC Grinding and Machining Center, a machine recognized for its superior processing capability, excellent dynamic performance, and strong adaptability to modern production needs.

Vertical CNC Machining Center Overview

A vertical CNC machining center positions the spindle in a vertical orientation, making it especially suitable for parts requiring gravity-assisted chip evacuation, simplified fixture design, and convenient workpiece loading. For many manufacturers, the vertical configuration is not only user-friendly but also space-efficient, making it ideal for small and medium-sized factories.

The JTGK-500F Pro fully showcases the strengths of a vertical CNC machining center. It is built for high-speed, high-precision, and high-efficiency machining operations, offering stable performance even during long-duration tasks. The machine’s generous travel distances—X/Y/Z travel of 500/400/230mm—allow flexible processing of various sizes of workpieces. With a worktable dimension of 530×430mm and a maximum workpiece height of 350mm, operators can handle a wide range of contour milling, engraving, and surface finishing jobs.

Another major advantage of this machine is its automatic tool magazine, which enables automatic exchange of multiple tool sizes. This feature dramatically enhances production efficiency, especially in batch jobs requiring frequent tool changes. To further simplify operation, the machine is equipped with the JIATIE CNC controller, known for its high compatibility, intuitive interface, and smooth man-machine interaction. For those asking “what is a CNC machining center?”, the JTGK-500F Pro provides a clear illustration: a highly integrated manufacturing platform combining precise motion control, multi-process capability, and flexible programming.

Horizontal CNC Machining Center Considerations

In contrast, horizontal CNC machining centers place the spindle horizontally and are often used for larger or heavier workpieces. They allow excellent chip evacuation due to gravity and can mount multiple fixtures on multi-sided tombstone setups. This configuration boosts throughput and reduces operator intervention during long cycles.

However, horizontal machines typically require larger floor space, more complicated fixtures, and higher investment costs. Many small and mid-sized manufacturers may not require the extreme throughput of a horizontal system.

For companies focusing on precision machining of mid-sized parts, the vertical CNC machining center configuration of the JTGK-500F Pro is often significantly more cost-effective. It offers faster setup, easier programming, and a shorter learning curve for operators.

Advanced Features for Multi-Face Machining

A major highlight of the JTGK-500F Pro is its compatibility with multi-axis machining functions. It supports an optional 4th axis CNC machining center setup, enabling multi-face machining in a single clamping. This reduces repositioning errors, saves time, and boosts machining accuracy for components requiring several machining surfaces.

For even more advanced applications, the machine can be upgraded into a 5 axis CNC machining center, allowing operators to process complex and highly contoured parts. This makes the machine suitable for industries such as aerospace, medical devices, molds, and high-end automotive parts.

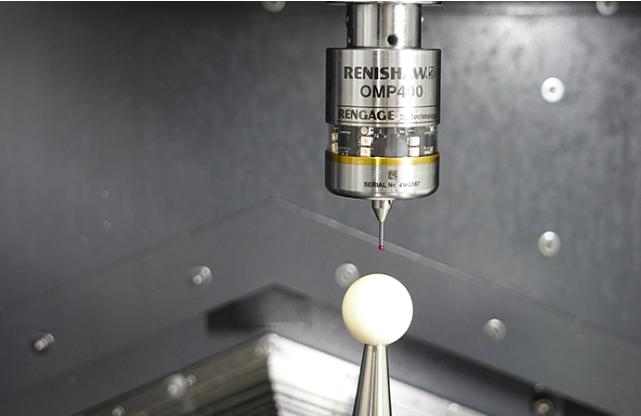

In addition, the machine supports an on-line measurement system. This real-time detection and correction technology drastically reduces deviation during sensitive machining processes. For parts susceptible to thermal deformation, warping, or positional precision issues, this feature ensures higher stability and improved yield.

Precision and Versatility

The JTGK-500F Pro is powered by a water-cooled CNC spindle, which helps maintain thermal stability and reduces heat-related deformation. This ensures long-term accuracy even in high-duty cycles or continuous operation environments.

The worktable supports up to 150 kg, making it suitable for a wide range of metal and non-metal materials. The overall dimensions—1550×1550×2400mm—and a sturdy 3000 kg net weight reflect its durable industrial structure. This robust build minimizes vibration and enhances machining accuracy, even during aggressive cutting tasks.

As a versatile platform, the JTGK-500F Pro can function both as a CNC engraving and milling machine and as a CNC engraving milling machine. Whether the production scenario involves fine engraving, mold processing, precision milling, or batch component machining, the machine delivers consistent output.

Its strong mechanical stability, dynamic rigidity, and compatibility with multiple cutting tools make it suitable for various materials, including aluminum, copper, graphite, composite materials, steel alloys, and high-hardness engineering plastics.

Real-World Applications

The flexibility and high precision of the JTGK-500F Pro make it ideal for a wide range of industries:

Automotive manufacturing – machining precision brackets, housings, and mechanical components

Aerospace and aviation – multi-surface machining for structural components

Electronics and communication – processing high-precision frames, connectors, and fine molds

Medical equipment – machining titanium and stainless-steel parts with tight tolerances

Molding industry – engraving patterns, shaping mold inserts, and contour milling

Graphite electrode manufacturing – due to its excellent fine-milling performance

Whether used in mass production or small-batch manufacturing, the JTGK-500F Pro offers stable performance and excellent machining repeatability.

Conclusion

Deciding between a vertical CNC machining center and a horizontal CNC machining center depends largely on production requirements, part geometry, budget, and available space. While Horizontal Machining Centers excel at handling heavy-duty, multi-sided machining in high-throughput environments, vertical CNC machining centers provide a more flexible and cost-effective solution for most manufacturers.

For companies seeking a high-precision, high-efficiency, and highly versatile machining platform, the JTGK-500F Pro CNC Grinding and Machining Center stands out as a powerful choice. It offers advanced vertical machining capability, optional multi-axis upgrades, automatic tool handling, real-time measurement systems, and superior dynamic performance.

In an era where precision and productivity define competitive manufacturing, the JTGK-500F Pro provides the ideal blend of speed, accuracy, reliability, and operational convenience—making it a valuable asset for any modern CNC production facility.