In modern manufacturing, precision and efficiency are paramount. A CNC vertical milling machine, also known as a vertical Machining Center, is a critical piece of equipment for industries ranging from automotive to aerospace and mold-making. These machines offer high-speed, high-precision operations for cutting, drilling, and shaping metal components. Among the latest innovations in this field, the JTVC-855P3 stands out as a versatile and reliable solution.

Understanding CNC Vertical Milling Machines

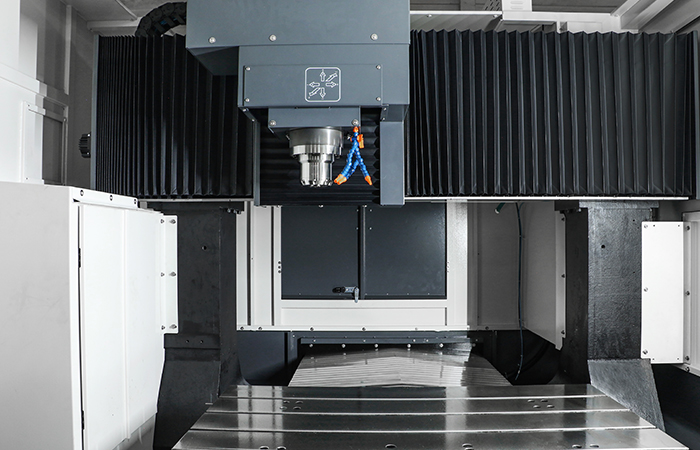

A CNC Vertical Machining Center is designed with the spindle oriented vertically, allowing tools to move along multiple axes to perform complex machining tasks. It integrates computerized control systems to automate cutting, drilling, and milling operations, providing higher precision and repeatability than manual machines. With vertical CNC capabilities, manufacturers can handle intricate designs and large workpieces efficiently.

Compared to traditional mills, a vertical milling center offers:

Enhanced accuracy and consistency

Reduced operator fatigue through Automation

Greater versatility for different materials and cutting techniques

JTVC-855P3: A High-Performance Vertical Machining Center

The JTVC-855P3 vertical machining center is engineered to meet the demands of modern production environments. Its specifications highlight both strength and precision:

X/Y/Z Travel: 800/500/550mm

Work Table Dimension: 1000x500mm

Maximum Workpiece Height: 500mm

Maximum Worktable Load: 800kg

Machine Net Dimension: 2580×2210×2750mm

Machine Net Weight: 4500kg

The machine’s robust structure ensures stability during high-speed milling, while the high-rigidity BT40 tool connector and powerful motor provide superior cutting performance.

Key Features of the JTVC-855P3

Arm Type Tool Magazine with 24 Tools

The JTVC-855P3 comes equipped with a 24-tool arm type tool magazine, allowing automatic tool changes and uninterrupted production. This is essential for multi-step machining processes and enhances operational efficiency.

Optimized Chip and Fluid Management

Two lateral slops lead to rear-side chip removal, while the cutting fluid is conveniently placed at the rear. This humanized design ensures clean operation and reduces downtime for maintenance.

Excellent Human-Machine Interaction

The vertical CNC machine features fully sealed protection and an intuitive interface, providing operators with a safe and convenient environment for complex machining tasks.

High Rigidity and Power

The combination of a BT40 high-rigidity tool connector and a strong motor ensures that cutting is stable, precise, and efficient, suitable for heavy-duty or high-precision components.

Applications of the JTVC-855P3 Vertical Machining Center

Thanks to its versatility and robust design, the JTVC-855P3 is ideal for various industrial applications:

Automotive Industry: Engine components, molds, brackets, and assemblies

Aerospace Components: High-precision parts requiring strict tolerances

Metal Fabrication and Mold Making: Complex geometries and multi-step processes

General Manufacturing: Heavy-duty machining of steel, aluminum, and other alloys

The vertical milling center allows manufacturers to achieve consistent quality while improving production speed.

Why Choose a CNC Vertical Milling Center?

A vertical CNC or CNC vertical machining center provides several advantages over traditional machining methods:

Automation: Reduces reliance on manual operations and minimizes human error

Precision: High repeatability ensures accurate components

Efficiency: Multiple tools and automated tool changes save time

Flexibility: Capable of handling different workpiece sizes and materials

Safety and Ergonomics: Fully enclosed systems protect operators and improve workflow

The JTVC-855P3 combines all these benefits, making it a reliable choice for manufacturers seeking a high-performance vertical machining center.

Conclusion

In the realm of modern manufacturing, the CNC vertical milling machine is an indispensable tool. The JTVC-855P3 vertical machining center exemplifies the latest in technology, offering precision, power, and operational flexibility. With its 24-tool magazine, optimized chip management, and robust design, this vertical CNC machine is ideal for high-demand production environments, ensuring efficiency, safety, and superior machining quality.

For industries looking to upgrade their vertical milling center capabilities, the JTVC-855P3 represents a perfect balance of innovation, performance, and reliability.