In today’s precision manufacturing environment, both Graphite Machining Centers and Standard CNC Milling Machines play vital roles in producing high-accuracy parts. However, as industries such as EDM, mold making, and semiconductor processing increasingly rely on graphite materials, the question becomes: Which machine is better suited for graphite machining?

1. Understanding the Core Difference

A Standard CNC Milling Machine is versatile and designed to process a wide range of materials including metals, plastics, and composites. However, graphite is a unique material. Its lightweight yet brittle structure, combined with its conductive graphite dust, demands a machine specifically built to handle its special properties.

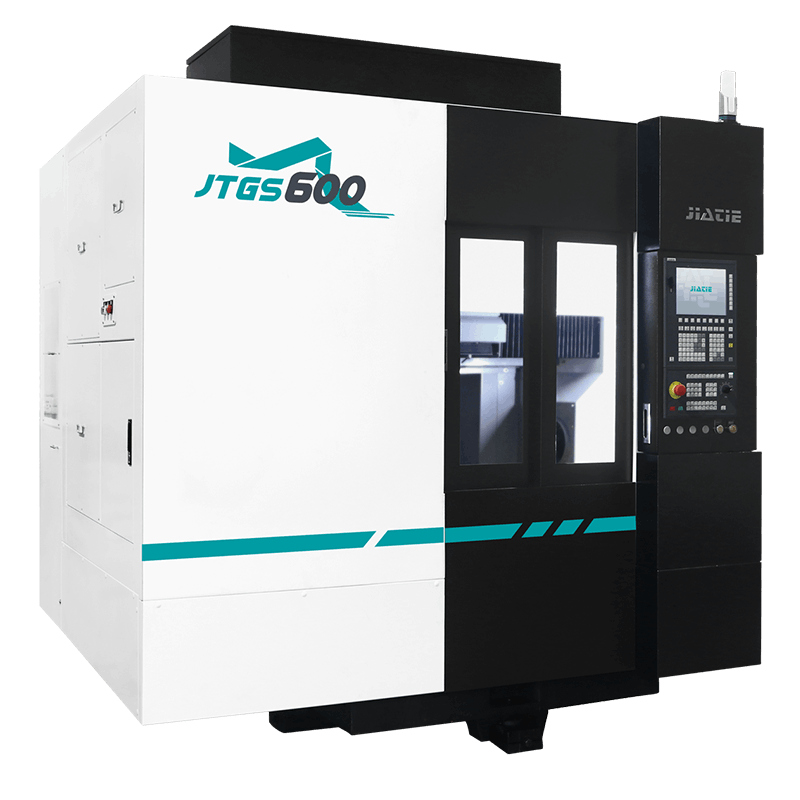

That’s where the Graphite Machining Center comes in. A graphite engraving and milling center like the JTGS-600 is purpose-engineered to deliver precision, dust control, and speed — key factors that a standard CNC milling machine struggles to achieve when machining graphite.

2. Introducing the JTGS-600 Graphite Machining Center

The JTGS-600 Graphite Machining Center represents a new generation of intelligent, high-performance graphite processing machines. Designed for professional-grade engraving, cutting, and finishing, it provides exceptional accuracy and efficiency for industries that demand tight tolerances and clean operations.

Technical Specifications

Parameter | JTGS-600 Graphite Machining Center |

X/Y/Z Travel | 600 / 500 / 300 mm |

Worktable Dimension | 630 × 500 mm |

Max Workpiece Height | 460 mm |

Max Worktable Load | 300 kg |

Machine Net Dimension | 2290 × 2180 × 2620 mm |

Machine Net Weight | 6500 kg |

Key Structural Features

Box-Type Structure Design

The JTGS-600 adopts a rigid box-type structure design, giving it excellent stability during high-speed cutting. This structure, combined with its unique damping characteristics, delivers outstanding dynamic machining performance, even under heavy loads or rapid acceleration.

Special Axis Protection System

The axis movement system uses special protective measures that shield critical moving components from graphite dust, significantly extending the lifespan of the linear guides, ball screws, and spindle assembly.

High-Speed and Precision Control

With rapid axis travel and optimized acceleration, the JTGS-600 supports high-speed feed cutting of graphite materials. Its control system ensures stable tool paths, minimal vibration, and smooth interpolation, which are critical for engraving and fine surface finishing.

Multi-Function Optional Design

The machine can be customized to meet different production needs, making it a flexible graphite engraving and milling machine for electrode machining, mold engraving, and precision component manufacturing.

Automation Compatibility

Designed with smart production in mind, the JTGS-600 can be integrated with automation systems such as robotic arms and pallet changers. This capability allows for continuous, unmanned operation, boosting output efficiency and productivity.

3. Graphite Machining Center vs Standard CNC Milling Machine

Let’s break down the main differences between a graphite engraving and milling center and a standard CNC milling machine:

Feature | Graphite Machining Center (JTGS-600) | Standard CNC Milling Machine |

Purpose | Specially designed for graphite processing | General-purpose for metal/plastic machining |

Machine Structure | Box-type design with damping for stability | Conventional column design |

Dust Protection | Fully enclosed with filtration system | Minimal or no dust control |

Cooling Method | Dry air cooling | Liquid coolant |

Spindle Speed | High-speed (up to 24,000 rpm) | Medium-speed (6,000–12,000 rpm) |

Tool Type | Diamond-coated tools for graphite | Carbide or steel tools |

Accuracy | ±0.003 mm positioning | ±0.01 mm positioning (typical) |

Maintenance | Low, thanks to protection and sealing | High, due to dust infiltration |

Automation | Supports robotic systems | Limited automation capability |

Applications | Graphite electrodes, molds, semiconductors | Metal parts, plastics, composites |

The JTGS-600 clearly outperforms traditional CNC machines in every area related to graphite machining — from precision and cleanliness to speed and long-term reliability.

4. Advantages of the JTGS-600 Graphite Machining Center

1. Superior Dynamic Machining Performance

Thanks to its box-type structure design and unique damping characteristics, the JTGS-600 offers exceptional rigidity and vibration absorption. Even during high-speed machining, it maintains stability, ensuring fine surface finishes and dimensional accuracy.

2. Extended Component Life

The special axis protection system prevents graphite dust — which is both abrasive and conductive — from entering the linear guideways and bearings. This protection dramatically extends the lifespan of moving components and reduces maintenance downtime.

3. High-Speed Feed and Precision Cutting

The JTGS-600 supports rapid axis movement and fast feed cutting, ideal for high-volume electrode and mold production. Its advanced servo system and high-speed spindle deliver smooth performance during complex 3D contouring operations.

4. Multi-Function Flexibility

Different industries have different machining needs. The JTGS-600 is designed as a multi-function graphite engraving and milling equipment, capable of performing roughing, semi-finishing, and finishing in one setup. This versatility increases workflow efficiency and reduces tool change time.

5. Automation Integration

In modern manufacturing, automation is key to competitiveness. The JTGS-600’s compatibility with robotic systems allows for continuous machining cycles, minimizing human intervention while maximizing throughput.

6. Clean and Safe Working Environment

Graphite dust can be harmful to both machines and operators. The JTGS-600 Graphite Machining Center is fully enclosed, with an efficient vacuum filtration system that captures fine dust particles, keeping the workspace clean and ensuring consistent performance.

5. Application Industries

The JTGS-600 Graphite Machining Center is widely used in industries requiring ultra-fine machining accuracy and cleanliness:

EDM Electrode Manufacturing:

Produces complex graphite electrodes with micron-level accuracy and superior surface finish.

Mold and Die Making:

Engraves intricate details and deep cavities in graphite molds with excellent repeatability.

Semiconductor and Electronics:

Machines graphite fixtures and components used in wafer processing and thermal management systems.

Aerospace and Defense:

Used for lightweight graphite composite parts where high strength-to-weight ratios are essential.

Automotive Industry:

Ideal for producing precision graphite molds used in EV battery components and connector housings.

In all these fields, the JTGS-600 serves as a high-performance graphite engraving and milling machine that guarantees stability, precision, and durability.

6. Cost, Efficiency, and Return on Investment

While the initial cost of a graphite engraving and milling center is typically higher than a standard CNC milling machine, the long-term value justifies the investment.

Lower Maintenance Cost

Dust protection, robust structural design, and minimal lubrication requirements reduce wear, meaning fewer repairs and replacements.

Higher Productivity

With automation options and rapid feed capabilities, the JTGS-600 significantly improves machining throughput, reducing per-part production cost.

Better Quality and Fewer Defects

Stable vibration control and precision motion translate to high-quality components, reducing scrap and rework.

Over time, these factors lead to a lower cost per part and a faster payback period, making the JTGS-600 Graphite Machining Center a smart investment for any graphite-focused production line.

7. Why Choose JTGS-600 Over a Standard CNC Machine

To sum up, the JTGS-600 Graphite Machining Center is the clear winner for graphite applications. While standard CNC machines may appear cost-effective initially, they struggle with graphite’s unique properties, often leading to higher tool wear, contamination, and lower accuracy.

The JTGS-600 solves these challenges by combining:

A rigid box-type design for stability

Special axis protection for durability

High-speed spindle and dry machining for efficiency

Automation readiness for future production scalability

If your business regularly processes graphite for EDM, molds, or semiconductor components, investing in a graphite engraving and milling center like the JTGS-600 ensures superior performance, cleaner operation, and higher profit margins.

8. Conclusion

When comparing a Graphite Machining Center with a Standard CNC Milling Machine, the difference is clear. A standard machine can cut graphite, but it can’t handle the dust, brittleness, and precision requirements effectively.

The JTGS-600 Graphite Machining Center stands out as a dedicated solution — delivering unmatched rigidity, precision, and reliability. Its box-type structure design, unique damping characteristics, and high-speed dry cutting performance make it an ideal graphite engraving and milling equipment for the most demanding production environments.

For manufacturers aiming to improve machining efficiency, part quality, and long-term operational stability, the JTGS-600 Graphite Machining Center is undoubtedly the better choice.