In the world of precision manufacturing, a Graphite Machining Center plays a pivotal role in producing molds, electrodes, and high-precision components. Whether you are in aerospace, automotive, electronics, or EDM (Electrical Discharge Machining) industries, the choice of a graphite engraving and milling machine can directly affect your productivity, quality, and operational efficiency.

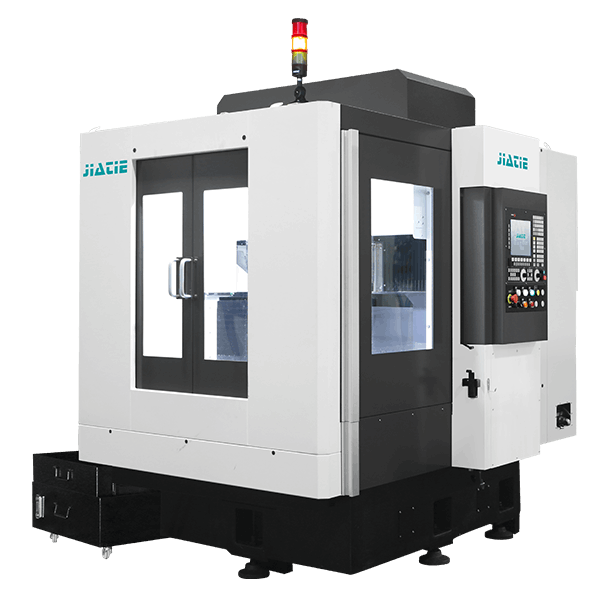

The JTGK-700i Graphite Machining Center stands out as a versatile solution for modern workshops. Engineered for speed, precision, and reliability, it combines advanced features that cater specifically to graphite engraving and milling equipment requirements. This article will guide you through the key features to consider when purchasing a Graphite Machining Center, using the JTGK-700i as a benchmark.

1. Understanding Graphite Machining Centers

A graphite machining center is a specialized CNC machine designed to cut, mill, and engrave graphite materials. Graphite’s brittle nature and fine dust generation require machines with high rigidity, excellent chip management, and dust-proofing.

Why Graphite Engraving and Milling Machines Are Essential

Precision electrode production: Essential for EDM molds.

Complex shapes: Graphite allows intricate geometries for electrodes and tooling.

High-speed machining: Reduces lead time for batch production.

Material versatility: Capable of handling graphite blocks of various densities and sizes.

Choosing the right machine ensures consistent quality, minimizes waste, and maximizes efficiency.

2. Introducing the JTGK-700i Graphite Machining Center

The JTGK-700i Graphite Machining Center is designed to meet the demands of high-precision graphite processing. Its combination of rigidity, precision, and Automation makes it a top choice for manufacturers.

Key Specifications

X/Y/Z Travel: 700 × 500 × 400 mm

Worktable Size: 900 × 600 mm

Spindle Speed: Up to 24,000 RPM

Tool Magazine: 16 tools, automatic tool change

Machine Weight: 3800 kg

With its robust structure, the JTGK-700i excels in continuous production, ensuring stability and accuracy, even at high cutting speeds.

3. Key Features to Consider When Buying a Graphite Machining Center

3.1 Rigidity and Structural Design

Graphite machining involves high-speed milling and engraving, which can induce vibration and tool wear. Look for a graphite engraving and milling center with:

Solid cast iron or reinforced frame: Minimizes deflection and vibration.

Finite Element Method (FEM) analysis: Ensures dynamic stability during high-speed operation.

Low-friction linear guides: Enhances smooth movement and accurate positioning.

JTGK-700i Advantage: The JTGK-700i is engineered with a fully rigid frame and optimized structural design, providing superior dynamic performance even during aggressive cutting.

3.2 High-Speed Spindle and Precision Tooling

A high-speed spindle is crucial for graphite machining, as it reduces chipping and improves surface finish. Key considerations include:

Spindle speed range: 20,000–25,000 RPM is ideal for fine engraving.

High-rigidity tool holder: Supports stable milling operations.

Automatic tool changer: Reduces downtime during complex jobs.

JTGK-700i Advantage: Equipped with a spindle capable of 24,000 RPM and BT30/BT40 high-rigidity tool connectors, the JTGK-700i offers precise, high-speed machining for both engraving and milling operations.

3.3 Tool Magazine and Automatic Tool Change

Efficient machining requires minimal interruptions. Machines with a tool magazine and automatic tool changer can switch between multiple tools quickly, improving productivity.

Considerations:

Tool capacity: Larger magazines reduce the need for manual intervention.

Reliability: Arm-type or carousel-type magazine designs are preferred.

Speed: Quick tool change minimizes idle time.

JTGK-700i Advantage: The JTGK-700i features a 16-tool arm-type magazine, offering fast, reliable, and repeatable tool changes for batch processing or complex multi-tool jobs.

3.4 Chip Management and Dust Control

Graphite dust is extremely fine and conductive, which can harm mechanical and electrical components. A top-quality graphite engraving and milling machine should provide:

Fully enclosed machining area: Prevents dust spread.

Chip conveyors or slopes: Direct debris away from the working area.

Vacuum extraction system compatibility: Ensures clean operation and safety.

JTGK-700i Advantage: Its enclosed working area and optimized chip removal system maintain a safe and efficient environment, reducing maintenance and improving operator safety.

3.5 Control System and Human-Machine Interface

The CNC control system determines the machine’s accuracy, ease of use, and adaptability. Features to look for include:

Advanced CNC software: Capable of 3D contouring and multi-axis operations.

User-friendly interface: Intuitive programming and operation.

Diagnostic and monitoring tools: Real-time feedback and error detection.

JTGK-700i Advantage: The machine is equipped with a high-performance CNC system that ensures smooth operation, precise positioning, and excellent human-machine interaction.

3.6 Precision and Repeatability

Graphite machining requires extremely tight tolerances for electrode production and mold-making. Important considerations:

Linear guideways and ball screws: Reduce backlash and improve precision.

Stable table and spindle: Maintains consistent surface finish and dimensional accuracy.

High-resolution encoders: Ensure repeatable positioning for batch production.

JTGK-700i Advantage: With precision linear guides, high-rigidity ball screws, and stable construction, the JTGK-700i maintains consistent machining accuracy even at high speeds.

3.7 Worktable Size and Load Capacity

Depending on the application, the machine must accommodate large graphite blocks and heavy workpieces. Features include:

Spacious worktable: Provides flexibility for larger components.

High load capacity: Ensures stability under heavy cutting forces.

JTGK-700i Advantage: The 900 × 600 mm worktable with high load support allows machining of various graphite workpieces, including large EDM electrodes and molds.

3.8 Cutting Fluid and Cooling System

While graphite is non-metallic, some operations benefit from mist or air cooling to reduce dust and maintain tool life. A reliable graphite engraving and milling equipment should support:

Coolant or air blast systems: Maintain surface finish and tool longevity.

Rear or side placement for efficiency: Ensures operator safety and convenience.

JTGK-700i Advantage: The JTGK-700i supports efficient chip and dust removal while providing optimal cooling options to improve cutting performance.

3.9 Maintenance and Durability

A well-built machine reduces downtime and ensures long-term operation. Look for:

Durable construction materials: Cast iron frames and coated guideways.

Easy access for maintenance: Simplifies routine lubrication and inspections.

Spare parts availability: Ensures minimal disruption in production.

JTGK-700i Advantage: Built with durable components and user-friendly maintenance access, it ensures years of reliable operation.

3.10 Software Integration and Automation

Modern graphite machining centers increasingly integrate with software for CAM programming, monitoring, and even robotic material handling. Benefits include:

Reduced setup time: Faster transition between jobs.

High-volume production efficiency: Automates repetitive processes.

Data tracking: Supports quality control and production optimization.

JTGK-700i Advantage: Compatible with most CAM software and ready for automated production environments, making it a smart choice for high-efficiency workshops.

4. Applications of the JTGK-700i Graphite Machining Center

The JTGK-700i Graphite Engraving and Milling Machine finds applications across multiple industries:

EDM Electrode Production: High-speed milling and engraving of complex electrode shapes.

Automotive: Precision molds, dies, and graphite tooling.

Aerospace: Components and electrodes for specialized parts.

Electronics: Engraving of graphite substrates and conductive molds.

Industrial Tooling: High-precision graphite dies for shaping metals and plastics.

Its combination of speed, precision, and reliability ensures consistent results for complex and repetitive tasks.

5. Conclusion

Choosing the right graphite engraving and milling center is critical for achieving precision, efficiency, and long-term operational success.

Key factors to consider include:

Rigidity and structural stability

High-speed spindle and precision tooling

Efficient tool magazine and automatic tool change

Dust-proof and chip management systems

Advanced CNC control and human-machine interface

Precision, repeatability, and worktable capacity

Maintenance ease and software integration

The JTGK-700i Graphite Machining Center excels in all these areas, making it a top-tier graphite engraving and milling machine for modern workshops. With its robust design, high-speed spindle, automatic tool magazine, and fully enclosed machining area, it delivers superior productivity, accuracy, and safety for high-precision graphite processing tasks.

Whether for batch production, intricate electrode creation, or complex mold manufacturing, the JTGK-700i graphite engraving and milling equipment ensures reliable performance and excellent ROI for manufacturers seeking a versatile and efficient solution.