What Is CNC Machining and Why It Matters

CNC machining (Computer Numerical Control) is a process that automates machine tool movement using programmed instructions. Instead of relying solely on manual operation, a cnc machine interprets digital design data to control cutting tools, ensuring precise and repeatable results.

This method is crucial for industries that demand tight tolerances and complex shapes. It allows manufacturers to produce identical parts with high accuracy, low waste, and consistent quality — something manual machining cannot achieve efficiently.

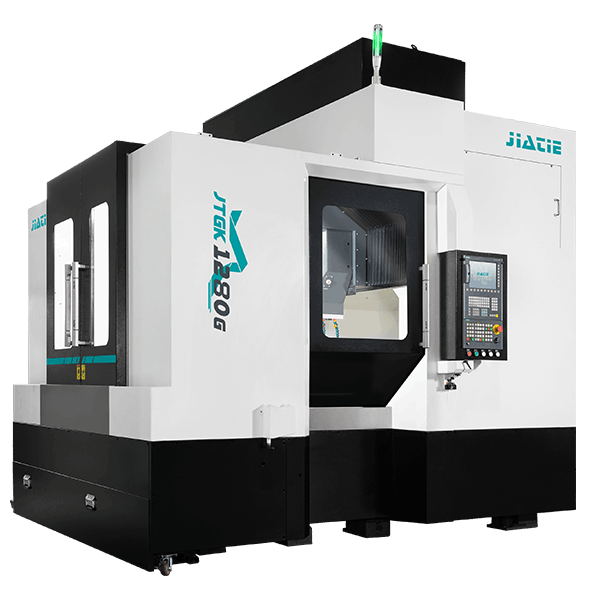

The JTGK-1280G CNC High Speed Machine: Overview

The JTGK-1280G is a premium CNC High Speed Machine designed for outstanding performance and stability. It delivers both high-speed and high-accuracy machining, meeting the growing demand for precision manufacturing.

Main Technical Specifications

X / Y / Z Travel: 800 / 1200 / 500 mm

The large travel range allows versatile processing of medium to large workpieces, enabling complex multi-axis machining.

Work Table Dimension: 800 × 1300 mm

This spacious table supports diverse tooling setups and multiple parts at once, enhancing productivity.

Max Workpiece Height: 600 mm

Capable of handling taller components for mold bases and mechanical housings.

Max Load of Worktable: 1500 kg

The table’s strong load capacity allows stable machining of heavy metal blocks and large dies without vibration.

Machine Dimensions:

2740 × 3430 × 3110 mm (Circular Tool Magazine)

2910 × 3430 × 3110 mm (Chain Tool Magazine)

Despite its large machining envelope, the compact footprint saves valuable floor space.

Machine Net Weight: 15,000 kg

The rigid 15-ton structure provides excellent damping performance and cutting stability during high-speed operations.

Features That Define the JTGK-1280G CNC High Speed Machine

High-Speed and High-Accuracy Machining Performance

Equipped with a globally recognized high-speed CNC control system, the JTGK-1280G delivers stable and reliable performance even under continuous heavy workloads. The fast spindle acceleration, smooth feed motion, and optimized cutting algorithms ensure high-quality surface finishes and exceptional geometric precision.

Advanced Structural Design

The newly designed mechanical structure increases overall rigidity. The base, column, and saddle are all optimized using finite element analysis to minimize vibration. This not only improves accuracy but also extends tool life—an essential benefit for any speed machine performing long production cycles.

Compact, Integrated, and User-Friendly

The all-in-one design provides a cleaner look and a smaller installation footprint. Operators benefit from easier access for setup, monitoring, and maintenance. The humanized layout makes operation intuitive, reducing training time and potential errors.

Optional Fully Closed-Loop System

For applications requiring ultra-high precision, the JTGK-1280G can be configured with a closed-loop feedback system. This ensures real-time positional correction for the X, Y, and Z axes, providing even greater machining accuracy and reliability.

Why CNC Machining Is Necessary

(1) Precision and Consistency

CNC technology ensures that every part produced meets design specifications exactly. With an accuracy level within microns, machines like the JTGK-1280G guarantee consistent part quality, which is vital for automotive and aerospace industries.

(2) Increased Speed and Productivity

As a cnc high speed machine, the JTGK-1280G minimizes idle time through rapid tool changes and high spindle speeds. Manufacturers can complete more parts in less time without sacrificing quality.

(3) Flexibility for Complex Designs

Modern designs often require intricate contours and 3D geometries. The JTGK-1280G handles these with ease, combining multi-axis movement and advanced control software to produce shapes impossible to achieve manually.

(4) Reduced Material Waste

Because of its precision and programming accuracy, this high speed machine minimizes cutting errors and material loss, providing significant cost savings, especially when machining expensive metals such as titanium or stainless steel.

(5) Lower Labor Dependence

Once programmed, the cnc machine operates autonomously, allowing technicians to manage multiple machines simultaneously. This reduces labor costs and increases efficiency across the production line.

Applications of the JTGK-1280G CNC High Speed Machine

The machine’s design allows it to serve multiple industries that depend on precision machining:

Industry | Application Examples |

Automotive | Engine blocks, transmission cases, brake molds |

Aerospace | Turbine blades, landing gear components |

Electronics | Aluminum housings, heat sink parts |

Mold Making | Injection molds, die-casting molds, plastic molds |

Medical Equipment | Surgical tools, implant prototypes |

Each of these sectors relies on the JTGK-1280G’s high-speed capability, accuracy, and ability to maintain stability even during prolonged production runs.

How the JTGK-1280G Enhances Production Efficiency

High Rigidity and Stability

The heavy 15,000 kg body and optimized casting structure provide excellent vibration absorption, ensuring smooth and steady performance even during aggressive cutting.

Large Worktable and Load Capacity

The 800×1300 mm table supports large workpieces, while the 1500 kg load rating allows for heavy mold bases and metal blocks to be processed safely and accurately.

Fast Tool Change System

Available with either a circular or chain-type automatic tool magazine, the JTGK-1280G reduces tool change time, improving cycle efficiency—a key factor in high-volume production.

Easy Maintenance and Long Service Life

Maintenance access is straightforward, and key components are designed for longevity. This makes the machine cost-effective over its operational lifespan.

Maintenance Tips for High-Speed CNC Machines

To keep a speed machine like the JTGK-1280G in top performance, regular maintenance is essential:

Daily Inspection: Check coolant and lubrication levels.

Spindle Monitoring: Listen for abnormal sounds and check temperature.

Guideway Cleaning: Remove chips and debris to avoid surface wear.

Tool Holder Maintenance: Keep tool holders balanced and clean.

Scheduled Calibration: Regularly check machine geometry to maintain precision.

Following these steps ensures longer life, higher productivity, and reduced downtime.

Conclusion: CNC Machining—The Backbone of Modern Manufacturing

From mold manufacturing to aerospace engineering, CNC technology forms the foundation of precision production. The JTGK-1280G CNC High Speed Machine exemplifies why CNC machining is not merely an option but a necessity for modern factories.

It combines high-speed machining, robust structural design, precision accuracy, and ease of maintenance, making it one of the most reliable tools for achieving consistent, high-quality results.

As industries evolve toward Automation and efficiency, machines like the JTGK-1280G will continue to drive progress, ensuring that manufacturers can meet global standards with confidence and speed.

In every sense, this cnc machine is a symbol of the future of intelligent, high-performance manufacturing.