Machining Centers

In precision manufacturing, especially in industries such as EDM electrode production, mold manufacturing, and semiconductor components, tool life plays a critical role in overall productivity and cost efficiency. The unique challenges of graphite machining—high abrasiveness, fine dust generation, and demand for ultra-precise surface finish—make tool wear and vibration control key concerns for manufacturers.

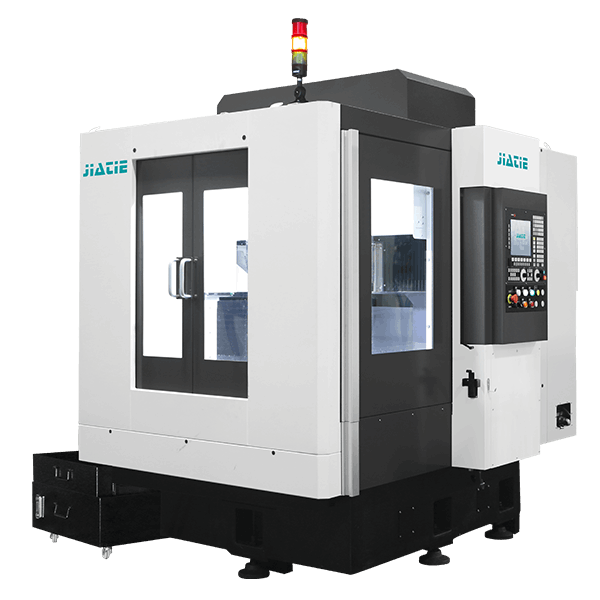

Modern graphite engraving and milling center technology addresses these challenges with innovative structural design, advanced damping systems, and high-performance spindles. One prime example of this evolution is the JTGK-700i Graphite Machining Center, a machine engineered to maximize tool longevity and ensure outstanding machining stability.

Why Vibration Control Matters in Graphite Machining

Graphite is an excellent material for applications such as EDM electrodes, but it is also highly abrasive. This accelerates tool wear, especially at high spindle speeds. Even minor machine vibration can worsen the problem, causing micro-chipping of cutting edges, reducing dimensional accuracy, and producing poor surface finishes.

Key Issues Caused by Vibration

Reduced Tool Life: Vibrations accelerate flank wear and chipping, forcing frequent tool changes.

Surface Finish Problems: Excessive chatter leads to rough surfaces that require secondary finishing.

Dimensional Inaccuracy: Micro-vibrations can shift tool paths, compromising part tolerance.

Spindle and Bearing Stress: Continuous vibration reduces machine component lifespan.

For these reasons, a graphite engraving and milling machine must offer exceptional structural rigidity and vibration suppression capability.

The JTGK-700i Graphite Machining Center: Designed for Stability

The JTGK-700i Graphite Machining Center is a dedicated solution for high-precision graphite machining, integrating a box-type structural design with unique damping characteristics to ensure superior stability during dynamic processing.

Key Specifications

X/Y/Z Travel: 500/700/230 mm

Work Table Dimension: 510 × 700 mm

Maximum Workpiece Height: 440 mm

Maximum Worktable Load: 300 kg

Machine Net Dimension:

2160 × 2400 × 2360 mm (Chain type tool magazine)

2120 × 2400 × 2360 mm (Circular type tool magazine)

Machine Net Weight: 5000 kg

This combination of a compact footprint, heavy weight, and carefully engineered frame provides the foundation for exceptional vibration damping.

Box-Type Structural Design: The Foundation of Rigidity

At the heart of the JTGK-700i is its box-type structural design, which significantly enhances machine rigidity. Unlike C-frame or lighter constructions, box-type frames distribute stress evenly, minimizing deformation under cutting loads.

Better Force Distribution: The closed structure allows cutting forces to be absorbed and dissipated efficiently.

Reduced Deflection: The machine resists bending, maintaining precise tool-to-workpiece alignment.

Enhanced Dynamic Stability: The combination of mass and geometry dampens vibrations at the source.

This means that even during heavy cutting or high-speed finishing passes, the graphite engraving and milling equipment maintains stable contact between the tool and the material, resulting in longer tool life and better surface finish.

Advanced Damping Characteristics

The JTGK-700i doesn’t rely on mass alone—it incorporates unique damping technology within its casting and assembly design.

Vibration Suppression: Internal damping materials and tuned structural stiffness absorb energy from spindle and table movement.

Consistent Machining Accuracy: Reduced vibration allows the machine to hold tight tolerances during long cycles.

Improved Tool Engagement: Smooth cutting conditions reduce micro-chatter, which helps preserve cutting edges.

This level of vibration control is critical in graphite engraving and milling center applications, where high-speed spindles (often 20,000–30,000 RPM) are standard and any instability would quickly damage the tool edge.

High-Speed, High-Accuracy Spindle

The JTGK-700i is equipped with a high-speed, high-accuracy spindle that makes its milling performance outstanding. The spindle’s precision bearings are carefully matched with the machine’s rigid frame, ensuring:

Minimal Runout: Better tool concentricity, reducing uneven wear.

Stable Cutting Forces: Less chatter and more predictable tool life.

Superior Surface Finish: Smooth cutting action produces fine detail and reduces post-processing.

Together, the spindle and damping structure enable this graphite engraving and milling machine to run at high speeds without sacrificing precision or accelerating tool degradation.

Fast Tool Change for Continuous Production

The machine’s servo type fast tool magazine supports rapid, reliable tool changes, minimizing downtime between operations. This feature is particularly useful when running small-diameter tools for engraving and larger cutters for roughing, as the machine can automatically switch tools without operator intervention, maintaining productivity.

Benefits of Enhanced Rigidity and Vibration Control

1. Extended Tool Life

Smooth cutting conditions mean less stress on cutting edges, delaying wear and chipping. This directly reduces tooling costs and machine downtime.

2. Improved Surface Finish

Reduced chatter produces superior surface finishes, reducing or eliminating secondary polishing operations.

3. Higher Productivity

Because the graphite engraving and milling center is more stable, it can run higher feed rates and spindle speeds safely, shortening cycle times.

4. Greater Consistency

Parts produced maintain tighter tolerances across long production runs, reducing rework and scrap.

Applications of the JTGK-700i Graphite Machining Center

Thanks to its stability and dust management features, this graphite engraving and milling equipment is ideal for:

EDM Electrode Production: High-precision graphite electrodes with fine detail and smooth surfaces.

Mold Industry: Core and cavity inserts with complex geometries.

Semiconductor Manufacturing: Graphite fixtures and carriers with micron-level tolerances.

General Industrial Use: Any graphite component requiring consistent quality and accuracy.

Conclusion

Enhancing tool life is about more than just choosing the right cutter—it requires a machine capable of delivering stable, vibration-free performance. The JTGK-700i Graphite Machining Center combines box-type structural design, advanced damping characteristics, a high-speed spindle, and excellent dust control to create the perfect platform for precision graphite machining.

By minimizing vibration, this graphite engraving and milling machine not only extends tool life but also improves surface quality, reduces production costs, and maximizes throughput. For manufacturers looking to achieve higher productivity and lower cost per part, investing in a machine like the JTGK-700i is a forward-thinking decision that ensures long-term competitiveness.