In today’s fast-paced manufacturing world, efficiency and precision are no longer optional — they are essential for survival and growth. For many companies, the challenge lies in upgrading their production lines without disrupting ongoing operations, while still meeting ever-tightening tolerance requirements and customer deadlines. This is where the JTGK-1280G comes in.

Our case study focuses on a mid-sized automotive parts manufacturer based in Europe. The company had been experiencing strong growth due to increasing demand for electric vehicle components. However, they faced a pressing challenge:

Their existing machines lacked the speed and precision required for newly contracted projects.

Production cycle times were too long, leading to missed deadlines.

Inconsistent accuracy required rework, reducing overall efficiency and increasing scrap rates.

Floor space in their facility was limited, preventing them from adding multiple new machines.

The production manager summarized the situation:

“We were at a crossroads. Either we found a way to boost throughput and accuracy with the same floor space, or we risked losing our biggest customer contract. We needed a solution that delivered speed, stability, and reliability — all in one package.”

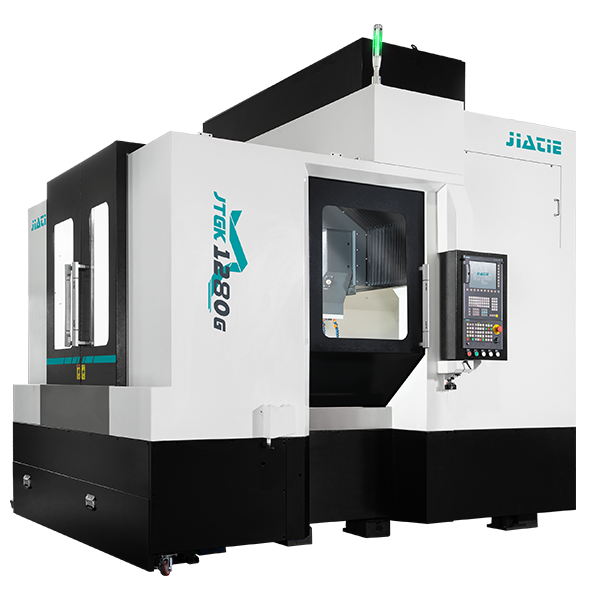

The Solution: Introducing the JTGK-1280G CNC High-Speed Machine

After carefully evaluating several suppliers, the company chose the JTGK-1280G CNC High-Speed Machine for its ability to meet multiple needs simultaneously. The decision was driven by several standout features:

High-speed and high-accuracy machining performance — allowing shorter cycle times without compromising precision.

Global high-speed CNC control system — ensuring stable and reliable performance under demanding conditions.

New machine structure design — delivering better machining performance while occupying less floor area.

Humanized, all-in-one design — making operation and management easier for the production team.

Temperature control technology — maintaining constant thermal conditions to achieve micron-level precision.

Jiate’s self-developed damping technology — ensuring consistent surface finish and geometric accuracy, even during prolonged machining.

For the manufacturer, the ability to perform roughing and finishing in a single setup was a major advantage. The high-rigidity bed and spindle structure allowed for aggressive cutting without compromising part accuracy, reducing repeated setups and maximizing throughput.

Implementation: Seamless Integration into the Production Line

One of the company’s concerns was how quickly the machine could be integrated into their workflow. Thanks to the JTGK-1280G’s all-in-one design, installation and commissioning took less than two weeks.

Operator training was straightforward due to the machine’s intuitive interface and humanized management system. Maintenance staff appreciated the easy-to-access design, which made routine checks faster and reduced downtime.

The production manager noted:

“The learning curve was surprisingly short. Within a month, our team was running the machine at full capacity, and the stability of the control system meant we had virtually no unplanned downtime.”

Results: Significant Performance Improvement

The results of implementing the JTGK-1280G CNC machine were immediate and measurable:

Production Efficiency Increased by 40%

The high-speed machining capability significantly reduced cycle times. Parts that previously took 20 minutes to complete were now finished in 12 minutes or less.

First-Pass Yield Improved to 98%

Thanks to the fully closed-loop system and advanced temperature control technology, dimensional accuracy improved dramatically. Scrap rates dropped, saving thousands of dollars per month in wasted materials.

Reduced Floor Space Usage

The compact footprint of the JTGK-1280G allowed the company to free up space for additional Automation equipment, further streamlining their production flow.

Lower Maintenance Costs

The robust design and long service life of the machine meant fewer breakdowns. Preventive maintenance schedules were easy to follow, reducing unexpected downtime.

Enhanced Employee Satisfaction

Operators found the machine easier to use compared to older equipment, reducing fatigue and human error.

Customer Feedback: Building Long-Term Trust

The company’s management team expressed their satisfaction with the solution:

“The JTGK-1280G CNC High-Speed Machine was more than just a machine purchase — it was a strategic upgrade. It allowed us to stay competitive in a demanding market and gave us the confidence to take on larger contracts. Our customers noticed the improvement in delivery times and part quality almost immediately.”

This positive experience strengthened the company’s relationship with its end customers and improved its reputation as a reliable supplier in the automotive supply chain.

Broader Impact: Setting a New Standard

The success story of this automotive parts manufacturer is not an isolated case. Many other industries — aerospace, electronics, and precision mold making — have also benefited from the JTGK-1280G CNC machine. Its combination of high-speed machining, structural rigidity, and micron-level accuracy makes it a versatile solution for enterprises looking to modernize their production lines.

By delivering both speed and precision in one machine, JTGK-1280G reduces the need for multiple setups, lowers production costs, and enhances product consistency — all critical factors for companies facing global competition.

Why This Matters for Future Buyers

For businesses considering an investment in a new cnc machine, the JTGK-1280G represents a safe and future-proof choice. Its advanced control system, robust design, and easy maintenance make it suitable for companies that want to scale up without sacrificing quality.

Key takeaways for potential buyers:

Performance and precision go hand in hand — You no longer need to compromise one for the other.

Compact footprint saves space — Ideal for factories with limited floor area.

Stable and reliable operation reduces risk — Ensuring long-term return on investment.

Humanized operation improves productivity — Shorter training times and less operator fatigue.

Conclusion

The story of how the JTGK-1280G CNC High-Speed Machine helped this automotive parts manufacturer achieve efficient production line upgrades is a powerful example of how technology can transform a business. By focusing on high-speed machining, precision, and ease of integration, this cnc machine has proven to be a reliable partner for companies seeking growth.

For any manufacturer looking to boost production efficiency, reduce costs, and maintain top-tier quality, the JTGK-1280G stands out as a smart, strategic investment. It is not just a piece of equipment — it is a catalyst for competitive advantage.