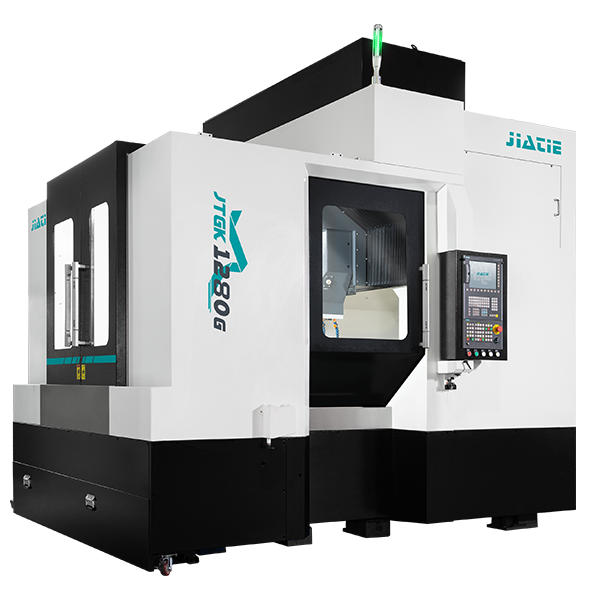

In today’s manufacturing industry, efficiency and precision are the two key factors that determine competitiveness. Especially in mold making, aerospace, automotive parts, and precision machinery, customers have increasingly strict requirements for machining accuracy and delivery times. To stay ahead in this competitive market, manufacturers must rely on advanced equipment. The JTGK-1280G CNC High Speed Machine is designed exactly for this purpose, offering outstanding high-speed machining performance, high precision, and enhanced stability, combined with a user-friendly design.

1. Advanced Design Ensures Stability and Accuracy

The CNC High Speed Machine JTGK-1280G adopts a brand-new machine structure design with superior rigidity and dynamic performance. This structural optimization minimizes vibration and deformation during high-speed cutting, resulting in higher machining accuracy.

The machine is equipped with a globally renowned high-speed CNC control system, which ensures stable and reliable performance. Unlike traditional machines that suffer from vibration and accumulated errors at high speeds, the JTGK-1280G maintains consistent precision even during complex operations.

Additionally, an optional fully closed-loop control system with high-precision linear scales provides real-time position feedback. This ensures repeatable accuracy and reliability, which is essential for producing complex parts and precision molds with fewer reworks.

2. Perfect Combination of High Speed and High Precision

The JTGK-1280G CNC High Speed Machine stands out with its outstanding high-speed and high-accuracy machining performance.

High-speed performance: Thanks to its optimized drive and transmission system, the machine achieves stable high-speed operations, reducing cycle times and greatly improving productivity.

High-precision performance: With low-friction guideways, rigid tool interfaces, and closed-loop control, the machine ensures micron-level accuracy even in demanding operations.

In practice, a mold part that may take 10 hours to complete on a standard CNC machine can be finished in just 6–7 hours on the JTGK-1280G, with higher accuracy and reduced finishing work.

3. Human-Centered Design for Better Operation and Management

Beyond hardware performance, this CNC High Speed Machine also emphasizes ease of use and operator safety:

All-in-one appearance design: With a compact footprint of only 2740×3430×3110 mm to 2910×3430×3110 mm, it saves valuable floor space and makes production line layout more flexible.

Fully enclosed protection: Provides operator safety and ensures a clean machining environment by preventing chip and coolant splashing.

User-friendly interface: Intuitive control panel reduces training time, allowing operators to master the machine quickly.

Easy maintenance: Modular design makes maintenance convenient, minimizes downtime, and the long service life reduces overall operating costs.

4. Improved Cutting Efficiency

The JTGK-1280G CNC High Speed Machine comes with a high-rigidity tool connector (HSK optional) and supports either a circular-type or chain-type tool magazine, meeting different production requirements. The circular type saves space, while the chain type offers larger capacity, ideal for multi-process or long-cycle machining.

Combined with a high-rigidity spindle and a powerful motor, the machine delivers superior cutting performance. It handles high-strength materials such as stainless steel, alloy steel, and titanium alloys with stability and efficiency. This not only increases output per unit time but also enables manufacturers to expand into more high-value machining applications.

5. Technical Specifications and Practical Value

The following specifications highlight the machine’s capacity for efficient and precise machining:

X/Y/Z Travel: 800 / 1200 / 500 mm – Large travel range for complex part machining.

Work Table Dimension: 800 × 1300 mm – Spacious table for flexible workpiece clamping.

Max Workpiece Height: 600 mm – Supports tall and three-dimensional parts.

Max Load of Worktable: 1500 kg – High load capacity ensures stability for heavy parts.

Machine Net Dimension:

2740 × 3430 × 3110 mm (Circular type tool magazine)

2910 × 3430 × 3110 mm (Chain type tool magazine)

Machine Net Weight: 15000 kg – Heavy-duty construction for rigidity and stability.

These parameters reflect not only the “hard strength” of the machine but also its contribution to higher productivity and accuracy.

6. Application Fields and Real-World Results

The JTGK-1280G CNC High Speed Machine is widely applicable in industries such as:

Mold manufacturing: Ideal for high surface quality and complex curved surfaces.

Aerospace: Suitable for machining high-strength, lightweight materials with stable precision.

Automotive parts: Ensures efficiency and consistency in mass production.

Precision machinery: Perfect for high-demand parts such as medical devices and optical components.

In real-world applications, manufacturers using the JTGK-1280G report 20–30% higher machining efficiency and a 15% reduction in scrap rates, which directly translates to higher profitability.

7. Conclusion

The JTGK-1280G CNC High Speed Machine delivers high-speed, high-precision machining, stable global CNC control, advanced structural design, user-friendly operation, and flexible configurations.

It not only reduces machining cycle times and increases first-pass yield rates but also lowers operating costs through reliable performance and long service life. For manufacturers aiming to achieve both efficiency and accuracy, this CNC High Speed Machine is a powerful solution that strengthens competitiveness in today’s fast-paced manufacturing landscape.