In the fields of mold manufacturing, precision parts production, and electrode processing, graphite machining has become an indispensable process. Graphite, with its excellent conductivity, high-temperature resistance, and machinability, is widely used in EDM electrodes, mold cavities, and advanced industrial components. However, the unique characteristics of graphite also place higher demands on machining equipment. Traditional Machining Centers often encounter issues such as dust pollution, accelerated tool wear, and limited efficiency when applied to graphite machining. Therefore, choosing a dedicated Graphite Machining Center has become essential.

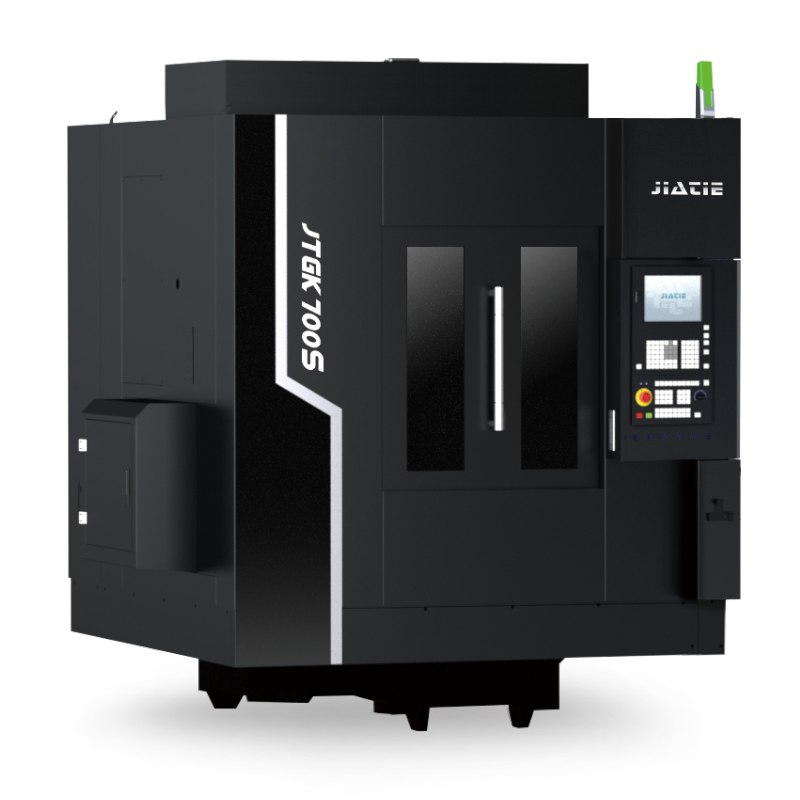

The JTGK-700S Graphite Machining Center is designed specifically for graphite applications. It not only outperforms traditional machining centers in dust resistance, wear resistance, and high-speed cutting but also excels in structural design, dynamic performance, and Automation compatibility. This article provides a comprehensive analysis of why the JTGK-700S Graphite Machining Center is the right choice, helping enterprises enhance their competitiveness in the manufacturing industry.

1. Limitations of Traditional Machining Centers in Graphite Machining

When used for graphite machining, traditional CNC Machining Centers often face the following challenges:

Poor Dust Control

Graphite generates a large amount of fine dust during cutting. This dust not only contaminates the environment but also enters key moving parts such as ball screws and guide rails, leading to reduced accuracy or machine failures. Traditional machining centers generally lack proper protective measures, resulting in higher maintenance costs and downtime.

Insufficient Wear Resistance

The abrasive nature of graphite cutting causes significant tool wear and accelerates the degradation of machine components. Conventional machines are not designed to withstand this, leading to shorter tool life and increased wear on motion systems.

Limited Efficiency

Since traditional machining centers are not optimized for graphite, their spindle speed, feed rate, and acceleration performance often fail to meet the demands of high-speed graphite cutting. This results in longer machining cycles and lower productivity.

Low Automation Compatibility

Modern manufacturing relies heavily on automation to boost efficiency. However, traditional machines are often poorly compatible with automated loading/unloading systems or tool changers, making it difficult to integrate them into intelligent production lines.

For these reasons, more and more companies are switching to dedicated graphite machining centers — and the JTGK-700S Graphite Machining Center provides the ideal solution.

2. Key Advantages of the JTGK-700S

1) Superior Structural Design: Box-Type Rigidity with Excellent Damping

The JTGK-700S adopts a box-type structure design with unique damping characteristics, ensuring outstanding dynamic stability during high-speed graphite cutting. This design effectively suppresses vibration, delivering consistent accuracy even in long machining cycles. It is particularly suitable for complex graphite electrodes and precision components.

2) Exceptional Dust Protection and Wear Resistance

The axis movement system of the JTGK-700S is equipped with special protective measures that effectively isolate graphite dust, preventing contamination of ball screws, guide rails, and other core components. This greatly extends the service life of moving parts. Combined with enhanced wear resistance, the machine maintains stability and reliability under long-term graphite machining.

3) High-Speed Cutting for Maximum Efficiency

The JTGK-700S supports rapid axis movement and fast feed cutting, fully leveraging graphite’s machinability. When machining electrodes, it significantly reduces cycle time and boosts overall productivity. Its high-speed spindle and responsive feed system make graphite machining more efficient compared to traditional machining centers.

4) Multi-Functional Configurations for Different Needs

Different businesses require different machining capabilities. The JTGK-700S offers multiple functional options, making it adaptable to a wide range of graphite machining applications — from large workpieces to complex electrode designs.

5) Automation-Friendly for Higher Output

The JTGK-700S can be integrated with automated loading/unloading systems and tool magazines, enabling continuous machining and even unmanned production. For enterprises producing graphite electrodes or precision parts in large volumes, this compatibility ensures greater competitiveness and efficiency.

3. Technical Specifications

Here are the main specifications of the JTGK-700S

X/Y/Z Travel: 700/500/300mm

Work Table Dimension: 700×500mm

Max Workpiece Height: 400mm

Max Load of Worktable: 300kg

Machine Net Dimension: 2100×2200×2400mm

Machine Net Weight: 5500kg

These specifications highlight the machine’s rigidity, load capacity, and versatility in graphite machining applications.

4. Advantages Over Traditional Machining Centers

Feature | Traditional Machining Center | JTGK-700S Graphite Machining Center |

Dust Protection | Minimal design, dust infiltrates critical parts | Specialized protection in axis system, effectively blocks graphite dust |

Wear Resistance | Rapid tool and guide wear, high maintenance cost | Designed for graphite, high wear resistance, longer lifespan |

High-Speed Cutting | Limited spindle/feed speeds, low efficiency | High-speed movement and fast cutting for maximum productivity |

Automation Compatibility | Poor integration with automation systems | Fully compatible with automation, ideal for smart manufacturing |

Dynamic Performance | Insufficient rigidity, prone to vibration | Box-type structure with damping, superior dynamic stability |

Clearly, the JTGK-700S surpasses traditional machining centers in nearly every aspect, making it the superior choice for graphite machining.

5. Application Scenarios

Graphite Electrode Manufacturing — Achieve faster cycle times and higher productivity through high-speed cutting.

Precision Mold Processing — Maintain superior quality and accuracy in mold cavity machining.

Aerospace Components — Ideal for graphite parts required in high-temperature environments.

Electronics Industry — Suitable for machining graphite heat dissipation elements and specialized parts.

These application examples demonstrate that the JTGK-700S is more than just a graphite machining center — it is a key enabler of industrial upgrading.

6. Conclusion: The Value of Choosing the JTGK-700S

In modern manufacturing, the importance of graphite machining continues to rise, and selecting the right equipment directly impacts both productivity and quality. Compared with traditional machining centers, the JTGK-700S Graphite Machining Center addresses key challenges with its dust protection, wear resistance, and high-speed cutting capabilities.

Its box-type structural design ensures superior dynamic performance, the axis movement protection system extends machine life, the high-speed cutting ability boosts efficiency, and its automation compatibility aligns perfectly with the trend toward intelligent manufacturing.

For enterprises engaged in graphite machining, the JTGK-700S is not just a machining tool — it is a strategic choice that enhances competitiveness, reduces costs, and ensures high-quality production.