In today’s fast-evolving manufacturing landscape, precision, speed, and efficiency are more important than ever. Enter the CNC machine, specifically the CNC High Speed Machine, which has transformed the way industries like automotive, aerospace, electronics, and precision engineering operate. But what exactly is a CNC High Speed Machine, and why is it considered a game-changer in modern manufacturing? This article provides a comprehensive overview of its definition, structure, key functions, and the advantages it brings to industrial production.

Definition of a CNC High Speed Machine

A CNC high speed machine is a computer-controlled manufacturing system designed to perform high-precision machining operations at significantly higher speeds than conventional CNC machines. It integrates advanced computer numerical control (CNC) technology with high-speed spindles, rapid feed rates, and automated tool handling to optimize production efficiency without compromising accuracy.

Unlike standard CNC machines, which may prioritize flexibility or heavy-duty cutting, CNC high speed machines are engineered for rapid material removal, precise finishing, and consistent high-volume production. They are particularly suited for applications where complex geometries, tight tolerances, and high throughput are essential.

Key performance metrics of CNC high speed machines include:

Spindle speeds: Up to 40,000 RPM for high-speed milling and micro-machining.

Feed rates: Exceeding 60 m/min, depending on material and tooling.

Positional accuracy: Typically within ±0.002 mm, ensuring precision for critical components.

Surface finish: Ra ≤ 0.2 µm achievable on metals and high-performance plastics.

Structure of a CNC High Speed Machine

A CNC high speed machine is composed of several integral components, each contributing to its speed, precision, and reliability:

1. Machine Base and Frame

The foundation of a CNC high speed machine is its rigid frame, often constructed from cast iron or composite materials to dampen vibrations. A stable frame ensures accuracy even at high spindle speeds, reducing chatter and deformation during machining. Some advanced machines use polymer concrete or granite for superior vibration damping.

2. Spindle System

The spindle is the heart of any CNC machine. In high speed machines, spindles are designed for high rotational speeds (up to 40,000 RPM) and low runout (typically below 2 µm). They can accommodate a variety of tool holders and cutting tools for different materials, enabling both roughing and finishing operations in a single setup.

3. Linear Guides and Ball Screws

Precision linear guides and ball screws ensure smooth and accurate movement along the X, Y, and Z axes. High-speed CNC machines employ preloaded ball screws with backlash below ±0.002 mm to maintain positional repeatability during rapid traverses.

4. Control System (CNC Controller)

A modern CNC controller serves as the brain of the machine, interpreting CAD/CAM designs and converting them into precise motion commands. High-speed CNC machines often feature adaptive control, real-time feedback, and diagnostic systems to monitor spindle load, tool wear, and vibration, ensuring consistent performance and minimizing downtime.

5. Tool Changer and Magazine

Automatic tool changers (ATC) allow the CNC machine to switch between multiple tools quickly, supporting continuous operation with minimal manual intervention. Tool magazines typically hold 20–120 tools, enabling complex multi-step machining without stopping the production line.

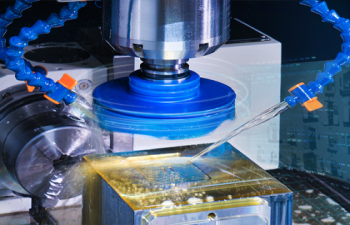

6. Cooling and Lubrication Systems

High-speed operations generate heat, which can affect tool life and part accuracy. CNC high speed machines are equipped with advanced cooling systems, such as high-pressure flood coolant or mist lubrication, to maintain optimal cutting conditions and extend tool longevity.

Key Functions of a CNC High Speed Machine

CNC high speed machines combine multiple machining processes into one highly automated system. Their primary functions include:

High-Speed Milling

Capable of rapid material removal with fine surface finishing, suitable for aluminum alloys, magnesium, and other lightweight metals. Spindle speeds and feed rates are optimized for minimal tool wear and maximum efficiency.

Precision Drilling and Boring

CNC high speed machines drill micro-holes for electronics, aerospace, and automotive applications, achieving diameters as small as 0.1 mm with high positional accuracy.

Complex 3D Contouring

Multi-axis configurations allow for simultaneous 3D contouring of complex geometries, such as turbine blades, mold cavities, or intricate automotive components.

High-Volume Production

With automated tool changing and pallet systems, CNC high speed machines can operate continuously, producing hundreds or thousands of parts with consistent quality.

Surface Finishing and Micro-Machining

High spindle speeds and precise control enable the creation of smooth surfaces suitable for coatings, anodizing, or microelectronics assemblies.

Advantages of CNC High Speed Machines

The benefits of integrating CNC high speed machines into modern manufacturing are significant:

Improved Productivity: Higher spindle speeds and feed rates reduce cycle times, enabling faster delivery of components. Production efficiency can improve by 30–50% compared to standard CNC machines.

Exceptional Precision: Tight tolerances and high repeatability reduce scrap rates and rework, essential in aerospace and automotive industries.

Material Versatility: CNC high speed machines can efficiently process metals, composites, and plastics, supporting diverse industrial applications.

Reduced Labor Costs: Automation features, including ATC and robotic integration, minimize manual labor and allow 24/7 lights-out operation.

Enhanced Surface Quality: Smooth finishes reduce or eliminate secondary finishing processes, saving time and cost.

Applications Across Industries

1. Automotive Industry

CNC high speed machines are used for engine components, transmission parts, suspension brackets, and custom prototypes. For example, aluminum cylinder heads are machined with high-speed spindles to ensure smooth coolant channels and precise combustion chambers. The result is improved engine efficiency and reduced scrap rates.

2. Aerospace Industry

Precision and lightweight materials are critical. CNC high speed machines manufacture turbine blades, structural panels, and landing gear components with tight tolerances . Multi-axis machining ensures aerodynamic efficiency and structural integrity.

3. Electronics Industry

For smartphones, laptops, and microelectronics, CNC high speed machines produce housings, connectors, and heat sinks with micro-level accuracy. Surface finishes meet aesthetic and functional requirements, while rapid production supports fast market cycles.

Maintenance and Care

Proper maintenance is crucial to sustain performance and extend the life of CNC high speed machines:

Daily: Clean chips, inspect tool holders, check coolant and lubrication levels.

Weekly: Inspect spindle runout, check linear guides and ball screws for wear.

Monthly: Calibrate axes using laser or ballbar systems, verify backlash within ±0.002 mm.

Annually: Replace worn bearings, overhaul the spindle system, and update CNC control software.

Regular maintenance ensures consistent accuracy, reduces downtime, and maximizes return on investment.

Conclusion

A CNC high speed machine represents the pinnacle of modern machining technology, combining speed, precision, and automation to meet the demands of today’s industrial landscape. Its structural innovations, advanced control systems, and multi-functional capabilities make it indispensable in automotive, aerospace, and electronics manufacturing. Companies adopting CNC high speed machines benefit from higher productivity, lower production costs, and superior part quality. As industries continue to demand faster, more precise, and more efficient manufacturing, the role of CNC high speed machines will only become more central to competitive success.