In today’s competitive manufacturing landscape, industries require highly specialized equipment to meet the demands of precision, efficiency, and flexibility. Among these advanced tools, the Long-Travel Machining Center has emerged as a pivotal solution for sectors that handle large or complex components. By customizing these machines for specific industrial applications, manufacturers can achieve higher precision, streamlined automation, and enhanced productivity.

Understanding Long-Travel Machining Centers

A Long-travel machining center is designed to handle workpieces that require extended movement along one or more axes. Unlike standard machining centers, which are optimized for smaller or medium-sized parts, these machines provide increased travel distances, allowing manufacturers to process oversized components with high accuracy. The extended capacity is particularly advantageous for industries such as aerospace, automotive, heavy machinery, and energy equipment, where large components are standard.

Customized Long-travel machining centers can incorporate advanced features such as reinforced frames, high-speed spindles, and integrated automation, making them adaptable to unique production requirements. By tailoring these machines to specific industrial workflows, manufacturers can optimize both efficiency and product quality.

Customization for Aerospace Applications

The aerospace sector demands components that meet stringent tolerance and safety standards. Aircraft fuselage sections, wing spars, and engine components often exceed the dimensions that conventional machines can handle. A CNC Machining Center with long-travel capabilities allows for precise machining of these large parts without the need for multiple setups, reducing the risk of errors and misalignments.

Additionally, customized configurations can include multi-axis heads, advanced tool changers, and real-time monitoring systems, enabling complex geometries to be machined with exceptional accuracy. Integrating a cnc vertical machining center design in long-travel configurations ensures that heavy components remain stable during machining, maintaining consistent precision across the entire workpiece.

Automotive Industry: Large Component Production

In automotive manufacturing, large chassis components, molds, and tooling plates require precision machining to ensure proper fit and performance. Standard vertical machining centers are often insufficient for these oversized parts. By customizing a Long-travel machining center, automotive manufacturers can streamline production of large components, reduce assembly errors, and maintain tight tolerances.

Customizations may include adjustable spindle speeds, extended X-Y-Z travel distances, and reinforced tables to accommodate heavy parts. Furthermore, incorporating cnc vertical machining center technology provides rigidity and vertical access, which is essential for machining complex geometries on car body panels and structural components. These enhancements enable manufacturers to produce high-quality components efficiently, even at scale.

Energy and Heavy Equipment Industries

Energy generation equipment, such as turbine housings, generator frames, and large industrial valves, often requires machining of heavy and oversized workpieces. Long-travel machining centers customized for these sectors can include specialized fixturing, pallet systems, and automated loading mechanisms, ensuring safe and precise handling of massive parts.

By integrating CNC Machining Center features, these machines can perform multi-stage operations without the need for re-clamping, reducing cycle times and improving repeatability. Advanced control systems also enable predictive maintenance and monitoring, minimizing downtime and extending the service life of both the machine and its tools.

Automation and Smart Factory Integration

Modern manufacturing emphasizes automation and connectivity. Customized Long-travel machining centers can be fully integrated into smart factory environments, enabling automated material handling, tool management, and real-time production monitoring. For industries that demand continuous operation, such as aerospace or energy, these features are invaluable.

Combining vertical machining center capabilities with long-travel configurations ensures that machines can handle both high-precision and high-volume operations simultaneously. Additionally, integrating cnc vertical machining center technology provides enhanced rigidity, spindle accuracy, and ease of programming, all of which contribute to seamless automated workflows.

Benefits of Customization

Customizing Long-travel machining centers for specialized industries offers several benefits:

· Precision and Accuracy: Tailored machines maintain tight tolerances across large workpieces, reducing errors and improving product quality.

· Efficiency: Customized configurations minimize setup times and enable continuous machining of oversized components.

· Flexibility: Machines can be designed for multi-axis operations, complex geometries, and various material types.

· Integration: Smart factory capabilities allow for real-time monitoring, predictive maintenance, and automated production processes.

· Cost Reduction: By reducing rework, errors, and downtime, Customized Machines lower overall production costs.

Choosing the Right Customized Solution

When considering a Long-travel machining center, manufacturers should evaluate several factors: the maximum workpiece size, required precision, material types, and integration with existing systems. Working with experienced machine tool providers ensures that each machine is optimized for the specific needs of the industry.

Customizations can include:

· Extended travel distances along X, Y, and Z axes

· High-rigidity spindle designs

· Multi-axis heads and rotary tables

· Automated tool changers and pallet systems

· Integration with ERP and production monitoring systems

Leveraging these features ensures that a cnc machining center or cnc vertical machining center is not only capable of handling large components but also contributes to an overall efficient and high-quality production process.

Conclusion

Customized Long-travel machining centers are transforming specialized industries by enabling precise, automated, and efficient machining of large and complex components. Whether in aerospace, automotive, or energy sectors, tailoring machines to specific workflows allows manufacturers to achieve superior quality, higher productivity, and competitive advantage.

By integrating advanced vertical machining center and cnc vertical machining center technologies, along with automation and smart factory capabilities, these long-travel machines become versatile tools capable of meeting the evolving demands of modern manufacturing. As industries continue to innovate, the role of customized Long-travel machining centers will only grow, shaping the future of precision engineering and large-scale production.

Company Introduction

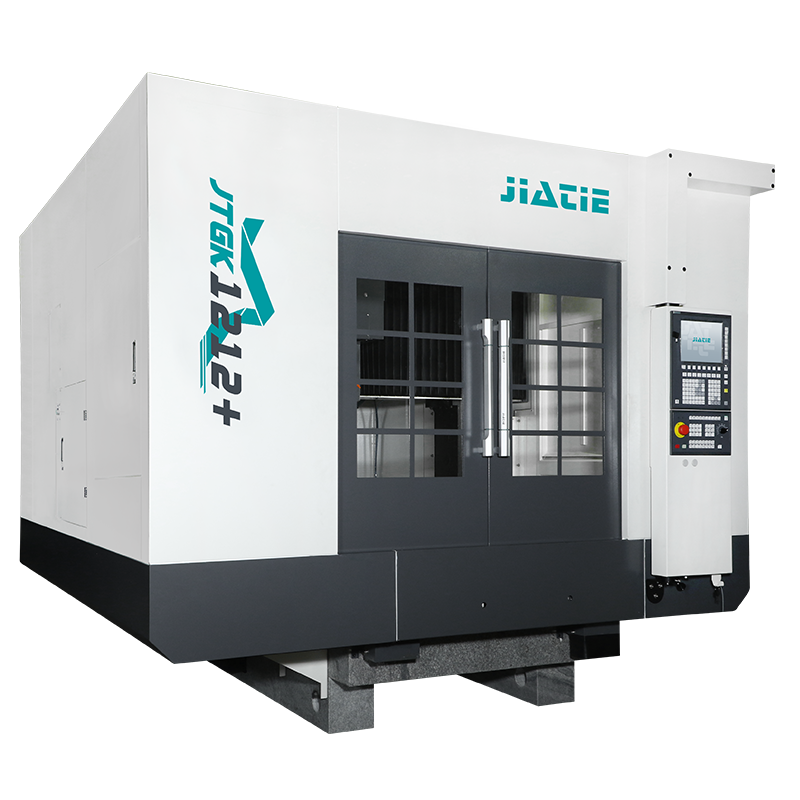

The brand ‘JIATIE’ of KEJIE TECHNOLOGY CO., LTD has been founded since 1998 for over 20 years, located in Jiangmen, Guangdong, China. It adheres to the motto ‘good and reliable quality as iron’ as the original entrepreneurial spirit.

Our products, including CNC grinding center, CNC high-speed machines, 5-axis high-speed machine, Vertical Machining Center, bonding machines, FPc soft-board laser cutting machines, automated production lines etc, are widely applied in different industries such as electronics, medical instruments, automotive, railway transportation, equipment manufacturing, molding industry, etc.

Up to now, the company maintains close cooperative relationships with various Global top 500 and Technology top 100 companies to provide customized solutions, and to achieve a win-win situation.

Contact: enquiry1@kejiegroup.com

Website: https://www.kejietechnology.com

YouTube:http://www.youtube.com/@kejie-w9j