Electrical Discharge Machining (EDM) has become a cornerstone of precision manufacturing, particularly in mold making, aerospace, medical, and electronics industries. At the heart of EDM technology lies the quality and precision of electrodes—most commonly made of graphite. To ensure consistent performance, manufacturers rely heavily on advanced graphite engraving and milling equipment to produce high-quality EDM electrodes. In this article, we explore why graphite machining centers are critical to the process and how they contribute to superior results.

The Importance of Graphite in EDM

Graphite is the preferred material for EDM electrodes due to its unique properties: high thermal resistance, good electrical conductivity, and ease of machining. Unlike copper, graphite can be cut faster, wears less during discharge, and handles complex geometries better. However, these benefits are only fully realized when the material is machined with precision—this is where a graphite engraving and milling center becomes indispensable.

Specialized Equipment for a Specialized Material

Standard CNC milling machines often fall short when it comes to machining graphite. The abrasive nature of graphite rapidly wears down cutting tools, generates fine dust, and demands precise control over cutting paths. Graphite engraving and milling machines are purpose-built to handle these challenges. They feature high-speed spindles, sealed enclosures, and advanced dust collection systems to maintain cleanliness and part accuracy.

Unlike general-purpose machines, a graphite engraving and milling center includes components optimized for Graphite Machining—such as linear guides, vibration dampening systems, and precise tool changers. These features ensure consistent surface finish and dimensional accuracy, even for complex and intricate EDM electrode geometries.

Accuracy and Surface Quality Matter in EDM

In EDM processes, the quality of the electrode directly affects the quality of the machined part. A poorly machined electrode can cause micro-cracks, uneven discharge, or dimensional inaccuracy in the final product. Therefore, the need for precision is non-negotiable. Graphite engraving and milling equipment ensures micron-level accuracy and minimal tool wear, leading to repeatable performance over long production runs.

The ability of a graphite engraving and milling machine to handle fine detailing, sharp corners, and deep cavities makes it ideal for creating electrodes used in intricate mold and die designs. Moreover, the high-speed capabilities reduce machining time, enabling faster production without compromising quality.

Integrated Dust Management: A Critical Advantage

One of the unique challenges of machining graphite is the fine dust it produces. If not properly contained, this dust can infiltrate machine components, reduce tool life, and pose health risks to operators. Modern graphite engraving and milling centers come equipped with advanced dust extraction systems, often with multi-layer filtration, to prevent contamination and ensure a clean working environment.

This not only protects machine longevity but also maintains the precision and consistency needed in high-tolerance EDM applications. Manufacturers benefit from lower maintenance costs and higher overall equipment effectiveness (OEE).

Automation and CNC Optimization

Today's graphite engraving and milling equipment is increasingly integrated with CNC automation and software solutions. This enables intelligent toolpath generation, real-time monitoring, and adaptive feed control. For large-scale EDM electrode production, such automation ensures consistent quality, reduces human error, and improves productivity.

With automated tool changers, material loading systems, and offline programming capabilities, a graphite engraving and milling center becomes a critical node in smart manufacturing environments focused on efficiency and scalability.

Applications Across Key Industries

Industries like automotive, aerospace, medical devices, and electronics depend on precision EDM to produce intricate and high-performance components. Graphite electrodes are used to create mold cavities, turbine blades, micro-cavities for connectors, and more. The versatility of graphite engraving and milling machines allows manufacturers to serve these diverse needs with confidence and agility.

Whether it’s producing high-precision micro-electrodes or large cavity molds, the adaptability of these specialized centers ensures consistent output across application types.

Conclusion: A Strategic Investment in Precision Manufacturing

As the demand for complex, high-precision components continues to grow, so does the need for reliable EDM processes. Investing in a dedicated graphite engraving and milling center is no longer a luxury—it's a strategic necessity. These machines offer the precision, speed, and reliability required to meet modern manufacturing standards.

With benefits ranging from superior surface finish and tool longevity to automation and dust control, graphite engraving and milling equipment forms the backbone of efficient EDM electrode manufacturing. For any business aiming to maintain a competitive edge in high-precision markets, this investment offers clear, measurable returns.

Company Introduction

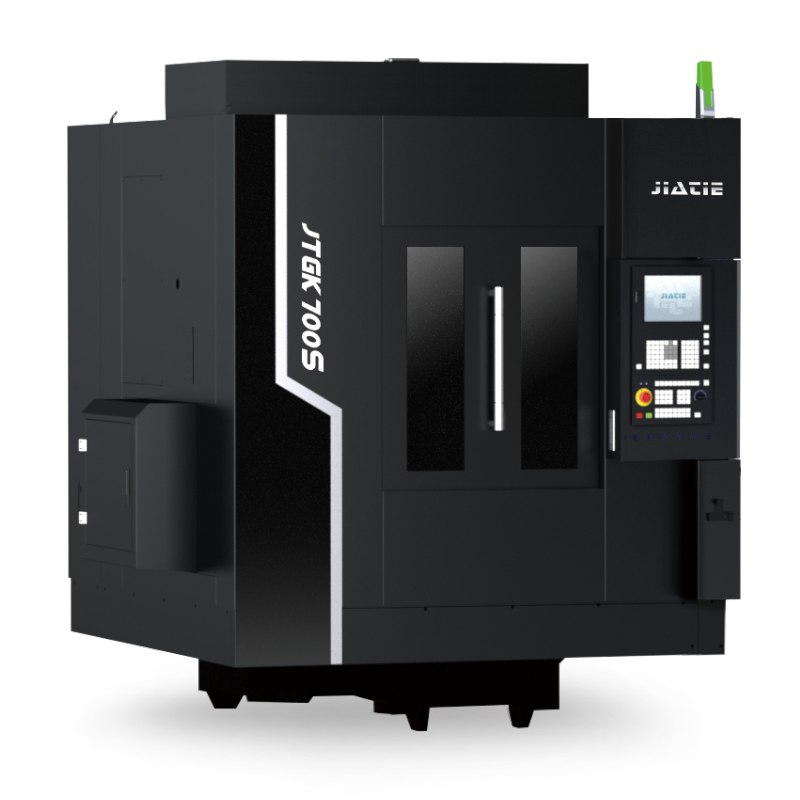

The brand ‘JIATIE’ of KEJIE TECHNOLOGY CO., LTD has been founded since 1998 for over 20 years, located in Jiangmen, Guangdong, China. It adheres to the motto ‘good and reliable quality as iron’ as the original entrepreneurial spirit.

Our products, including CNC Grinding Center, CNC high-speed machines, 5-axis high-speed machine, vertical Machining Center, bonding machines, FPc soft-board laser cutting machines, automated production lines etc, are widely applied in different industries such as electronics, medical instruments, automotive, railway transportation, equipment manufacturing, molding industry, etc.

Up to now, the company maintains close cooperative relationships with various Global top 500 and Technology top 100 companies to provide customized solutions, and to achieve a win-win situation.

Contact: enquiry1@kejiegroup.com

Website: https://www.kejietechnology.com

Youtobe: http://www.youtube.com/@kejie-w9j