In today’s highly competitive manufacturing environment, productivity, precision, and long-term stability are no longer optional—they are essential. As part complexity increases and delivery cycles shorten, manufacturers are re-evaluating their equipment strategies. One of the most important decisions facing factories today is whether to rely on traditional CNC machining or invest in a CNC High Speed Machine.

This article provides a comprehensive comparison between high speed CNC technology and traditional CNC machining, analyzing their differences in structure, performance, accuracy, tooling, applications, and return on investment. It also highlights how modern machine designs—equipped with a new generation CNC control system, advanced temperature control, and high-rigidity structures—are redefining machining efficiency.

Understanding Traditional CNC Machining

Traditional CNC machining refers to numerically controlled milling, drilling, and cutting operations performed at relatively moderate spindle speeds and feed rates. These machines are widely used as general-purpose nc machine tools, valued for their robustness and versatility.

Characteristics of Traditional CNC Machining

Moderate spindle speeds

High cutting torque

Strong mechanical rigidity

Suitable for heavy roughing operations

Compatible with a wide range of tools CNC milling

Traditional CNC machines excel at machining steel, cast iron, and other hard metals where high cutting force is required. However, as part designs become more complex and surface quality demands increase, traditional machining begins to show limitations.

What Is a CNC High Speed Machine?

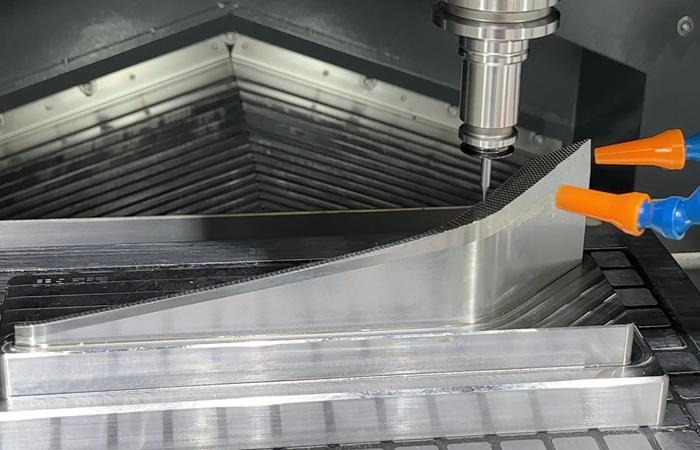

A CNC high speed machine is designed to operate at significantly higher spindle speeds and feed rates while maintaining extreme accuracy and stability. Rather than relying on heavy cutting forces, high-speed machining focuses on precision motion, reduced cutting resistance, and efficient chip evacuation.

A modern high speed CNC center integrates:

High-speed, high-precision spindles

Advanced servo and motion control

Lightweight yet rigid machine structures

Intelligent thermal compensation systems

These machines are commonly used in mold making, aerospace, automotive tooling, electronics, and aluminum or graphite machining.

Key Structural Differences

Machine Structure and Rigidity

Traditional CNC machines often rely on heavy cast structures to absorb vibration. In contrast, a CNC high speed machine uses a new structural design that balances rigidity with dynamic performance.

New structure design improves machine rigidity, ensuring stability during high-speed movement

Optimized mass distribution improves acceleration and deceleration

Reduced vibration enhances surface finish and tool life

For large-format or high-precision applications, a fixed gantry CNC structure is frequently used in high-speed machining. This design provides excellent symmetry, high stiffness, and consistent accuracy across the entire working envelope.

Control Systems and Motion Performance

One of the most critical differences lies in the CNC control system.

Traditional CNC Control

Focuses on basic interpolation accuracy

Limited dynamic optimization

Less capable of handling complex tool paths at high speed

High-Speed CNC Control

A new generation CNC control system enables:

High-speed data processing

Smooth multi-axis interpolation

Advanced acceleration/deceleration control

Real-time error compensation

This allows a high speed CNC machine to maintain precision even at very high feed rates, something traditional CNC systems struggle to achieve.

Thermal Stability and Long-Term Accuracy

Thermal deformation is a major source of machining error, especially during long production runs.

High-speed CNC machines integrate:

Temperature control technology

Intelligent thermal sensors

Structural compensation algorithms

As a result, long-term accuracy is stable, even during extended high-speed operation. Traditional CNC machining often requires slower cutting speeds or frequent pauses to control heat buildup.

Speed, Productivity, and Cycle Time

Traditional CNC Machining

Longer cycle times for complex parts

Multiple setups often required

Slower finishing operations

CNC High Speed Machine

Shorter cycle times by 30–70%

High feed rates with stable accuracy

Complex surfaces completed in a single setup

A high speed CNC center dramatically improves productivity, especially in mold cavities, thin-wall components, and 3D contour machining.

Surface Finish and Part Quality

Surface quality is one of the strongest advantages of high-speed machining.

Machines such as a Makino CNC mill are well known for delivering superior surface finishes that often eliminate secondary polishing or grinding.

High-speed machining achieves this by:

Maintaining constant cutting engagement

Reducing vibration

Using optimized tool paths

Traditional CNC machining typically produces acceptable finishes but often requires additional post-processing for high-end applications.

Tooling Requirements and Tool Life

Tooling strategy differs significantly between the two technologies.

Traditional CNC Tooling

Emphasizes strength and durability

Larger cutting tools

Designed for heavy material removal

High-Speed CNC Tooling

Lightweight, balanced tools

Advanced coatings

Optimized for high RPM and low cutting force

Modern tools CNC milling machine systems designed for high-speed operation often experience longer effective tool life due to reduced cutting stress, despite higher spindle speeds.

Work Envelope and Load Capacity

A typical modern high-speed CNC Machining Center may feature specifications such as:

X/Y/Z travel: 600 / 500 / 320 mm

Work table dimension: 680 × 500 mm

Max workpiece height: 380 mm

Max load of worktable: 300 kg

Machine net dimension: 2760 × 2200 × 2530 mm

Machine net weight: 7000 kg

These specifications demonstrate that high-speed machines are not limited to small or lightweight parts—they can handle substantial workpieces while maintaining speed and precision.

Application Comparison by Industry

Mold and Die Manufacturing

High-speed CNC machines dominate finishing operations due to their superior surface quality and accuracy. Traditional CNC machines are often used for roughing, while finishing is completed on a high speed CNC center.

Aerospace Industry

Lightweight alloys and complex geometries benefit significantly from CNC high speed machine technology, reducing deformation and improving consistency.

Automotive Tooling

Both technologies coexist. High-speed CNC is used for molds, dies, and aluminum parts, while traditional CNC machining remains effective for steel fixtures and brackets.

Electronics and Precision Components

High-speed CNC machining is essential for thin walls, micro-features, and high-density components where traditional CNC tools lack the required precision.

Energy Efficiency and Operating Costs

Although a CNC high speed machine typically requires a higher initial investment, it often delivers lower cost per part due to:

Reduced machining time

Fewer finishing processes

Lower scrap rates

Higher Automation potential

Traditional CNC machining remains cost-effective for low-volume or heavy-duty applications but may struggle to match the efficiency of high-speed systems in complex production environments.

Integration with Smart Manufacturing

High-speed CNC machines are better aligned with Industry 4.0 initiatives, offering:

Real-time monitoring

Predictive maintenance

Data-driven optimization

This makes them ideal for smart factories aiming to improve uptime and overall equipment effectiveness (OEE).

Choosing Between High-Speed and Traditional CNC Machining

When selecting the right solution, manufacturers should consider:

Material type

Part complexity

Required surface finish

Production volume

Long-term ROI

In many cases, a hybrid strategy—combining traditional CNC roughing with high-speed CNC finishing—offers the best balance of cost and performance.

Conclusion

The comparison between CNC high speed machines and traditional CNC machining reveals a clear technological shift. While traditional nc machine tools remain essential for heavy-duty and general-purpose applications, high-speed CNC technology has become indispensable for precision, efficiency, and advanced manufacturing.

With features such as a new generation CNC control system, advanced temperature control technology, and high-rigidity structural design, modern high speed CNC centers deliver unmatched productivity and surface quality.

From premium systems like the Makino CNC mill to large-scale fixed gantry CNC solutions, high-speed machining is setting new standards for industrial manufacturing. For companies seeking to remain competitive in precision-driven markets, investing in CNC high speed machine technology is no longer a luxury—it is a strategic necessity.